In industries like oil and gas, shipbuilding, and power generation, the demand for precise machining is crucial, even in challenging environments. Traditionally, metalworking required transporting heavy workpieces to a dedicated workshop, but portable machine tools have changed the game. By bringing the tool to the worksite, these tools simplify complex repairs, reduce downtime, and make high-quality machining achievable in the most remote conditions. In this blog, we’ll explore the top reasons to consider portable machine tools for your on-site metalworking projects.

Portable machine tools offer a unique solution for on-site machining, allowing companies to bypass the costly and time-consuming process of transporting equipment to a traditional workshop. This innovation enables efficient, precise repairs while minimizing downtime. Here, we’ll break down the core benefits of portable machining and why it’s worth considering for your next project.

With the increasing popularity of portable machine tools, let’s explore some of the most compelling reasons to adopt this technology. Whether it’s the challenges of moving large workpieces, the precision required on-site, or the flexibility these tools provide, portable machining is transforming how industries handle repairs and maintenance.

What Challenges Arise in Transporting Large Workpieces to a Fixed Workshop for Machining?

When heavy machinery or industrial components need machining, transporting them to a workshop is often a logistical challenge. From cranes to heavy-duty vehicles, transporting large workpieces is complex, expensive, and time-consuming. Portable machine tools eliminate this hassle by allowing you to bring the machining operation to the worksite.

Transporting workpieces is often a multi-step process, involving disassembly, securing permits, arranging transportation, and reassembly-each step adding time and cost. Portable machines remove these barriers, allowing for on-site work that’s faster and more straightforward.

Taking a large workpiece off-site often means disassembling equipment, which can affect alignment and structural integrity. Additionally, the process of reassembling and calibrating a workpiece after it’s machined elsewhere adds downtime. Portable machine tools let operators machine parts directly on-site without disturbing their setup, making repairs faster and preserving accuracy.

How Do Portable Machine Tools Enable Precise Metalworking Tasks in Locations with Limited Access or Remote Conditions?

Working in remote or confined spaces can pose major challenges for metalworking. Portable machine tools are designed to perform with the same level of precision as in-shop equipment, even in locations with limited accessibility. They enable high-quality machining where it would otherwise be impossible to bring traditional machinery.

Portable tools are built for accessibility and precision in challenging locations. They allow skilled operators to perform complex operations, such as line boring, milling, and flange facing, in any setting. This capability is crucial for industries operating in remote areas or confined environments.

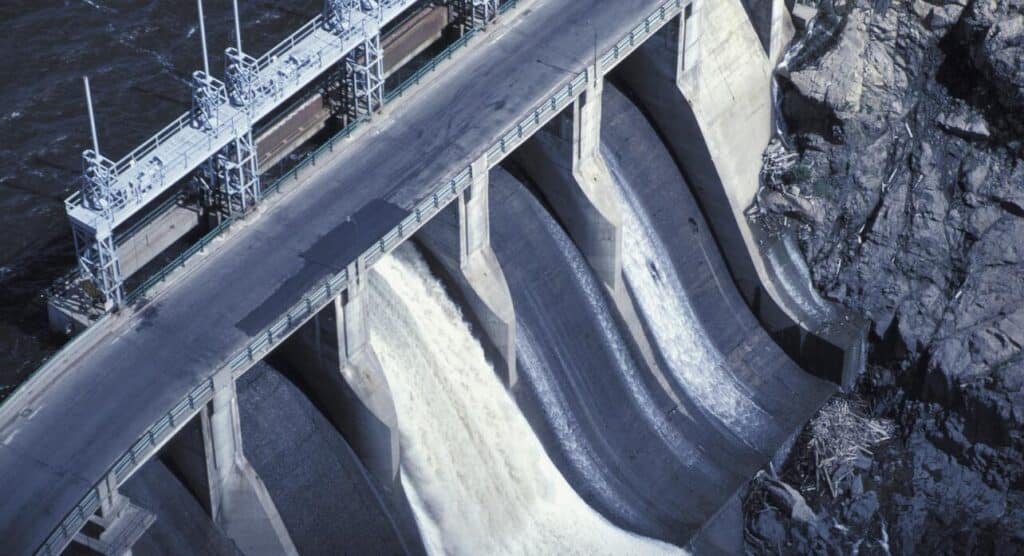

For industries with operations in remote locations, like offshore drilling rigs or wind farms, portable machine tools are a game-changer. These tools are compact, easy to transport, and can be used in tight spaces where large equipment wouldn’t fit. On-site machining also removes the need for multiple handling and re-alignment of parts, ensuring a high degree of precision and efficiency in difficult conditions.

Why Is Using Portable Machine Tools Often More Cost-Effective Than Moving Workpieces to a Workshop?

Cost efficiency is one of the most significant advantages of using portable machine tools. Traditional machining requires disassembly, transport, reassembly, and calibration-all of which can drive up costs significantly. By bringing the machine to the workpiece, companies can avoid these expenses while achieving the same precision in machining.

The costs saved by avoiding disassembly, transport, and reassembly are substantial. With portable machining, repairs can often be completed faster, directly at the source, reducing the financial impact of both transportation and extended downtime.

In addition to eliminating transportation costs, portable machine tools can reduce hidden expenses. For instance, many workpieces require exact alignment, which is difficult to maintain during disassembly and transport. The ability to perform precision machining on-site minimizes disruption and ensures that parts remain in optimal working condition, reducing overall repair costs and improving operational efficiency.

How Can Portable Machine Tools Enhance Productivity and Flexibility in Completing Repair and Maintenance Tasks On-Site?

Portable machine tools streamline repair and maintenance tasks by providing flexibility and reducing downtime. These tools allow work to be completed directly on-site, which means less waiting, fewer interruptions, and a more efficient use of resources.

With portable machining, repairs can be scheduled and completed in a fraction of the time required for off-site work. This increased flexibility makes it easier to maintain tight production schedules, and it gives operators control over timing and task completion, optimizing productivity.

On-site machining means that repairs are only limited to the actual time spent working on the piece, as there is no delay for transport or setup in a secondary location. Additionally, portable machine tools allow for faster maintenance intervals and less impact on other ongoing processes. These tools provide adaptability, letting operators carry out repairs or modifications without waiting for external facilities, resulting in greater overall productivity.

Conclusion

Portable machine tools offer a transformative approach to on-site metalworking, addressing the logistical, cost, and productivity challenges associated with transporting large workpieces. By bringing precision machining directly to the workpiece, these tools enable companies to improve efficiency, reduce downtime, and maintain high standards of accuracy-even in challenging or remote environments. For industries that depend on timely, precise repairs, portable machining represents a powerful solution that boosts productivity, cuts costs, and increases flexibility, all while minimizing the impact on ongoing operations.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.