Why Use a Portable Keyway Milling Machine for Oversized or Fixed Workpieces?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

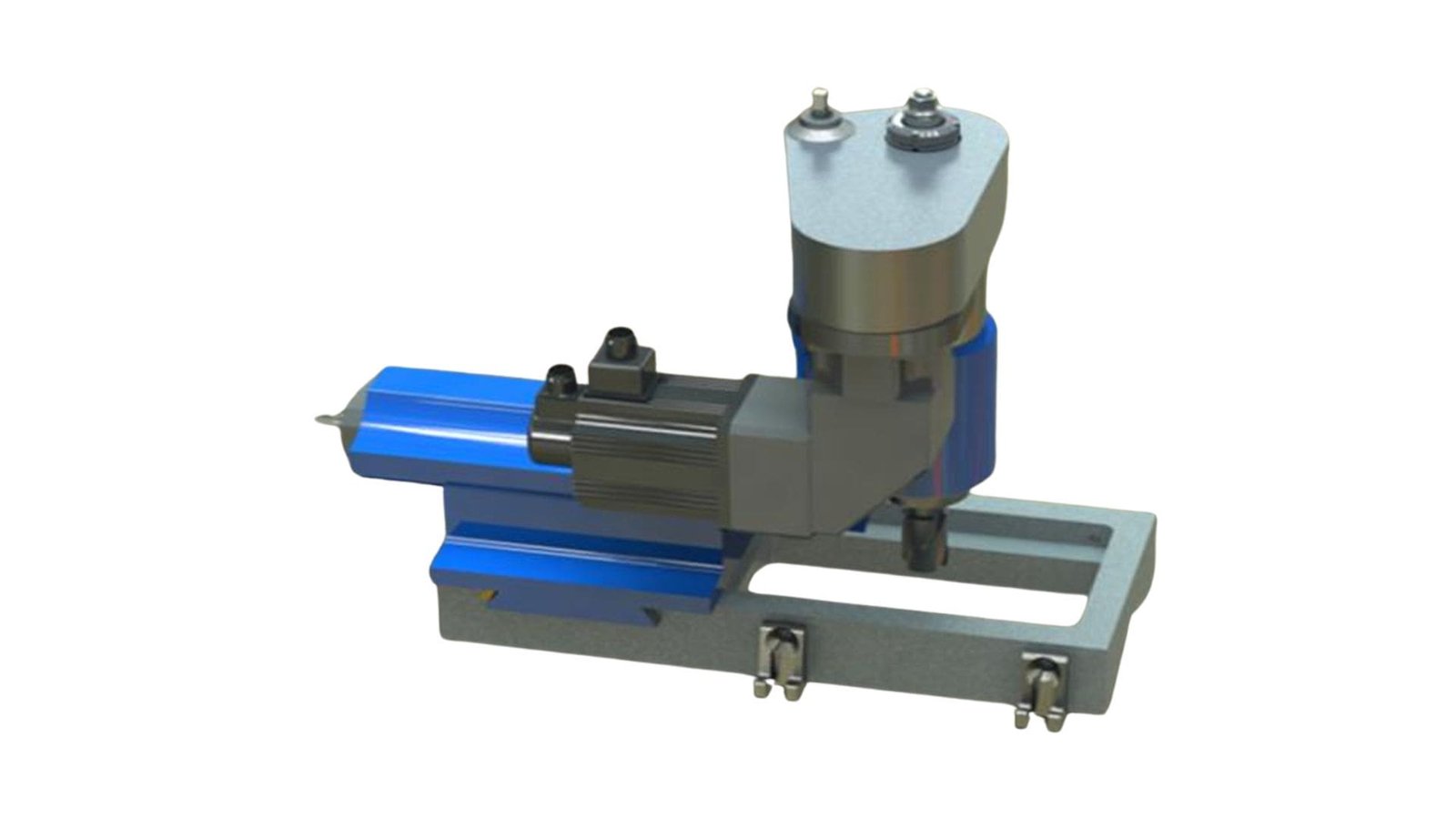

Got a massive shaft, maybe up to 24 inches in diameter, or a huge piece of machinery needing a precise keyway, slot, or flat, but it’s impossible to move? Trying to machine it on a standard workshop mill is out of the question. You’re facing significant disassembly or transport costs.

Use a portable keyway milling machine because it brings the machining capability directly to the large or fixed workpiece in situ, eliminating costly disassembly, transportation, and reassembly. It’s designed for on-the-spot precision work on shafts and surfaces.

Bringing the machining capability directly to the workpiece is a game-changer, especially in heavy industry or field repairs. Whether it’s a small shaft around 0.75 inches or a giant one up to two feet wide, these machines adapt. Imagine a large gearbox deep within a ship’s hull or a massive rotor shaft in a power plant – you simply can’t take those to the machine shop easily. A portable miller solves this efficiently. Let’s explore the precision you can expect.

What Level of Accuracy and Surface Finish Can Be Expected When Milling Keyways with a Portable Machine?

Worried that "portable" means sacrificing precision? When you need a keyway, slot, or flat, it must meet specifications. Tight tolerances and a good surface finish are vital for proper fit and function. Can a machine clamped onto a part really deliver workshop quality?

High accuracy and good finishes are definitely achievable. These machines often feature precision components like dovetail ways and calibrated dials (to 0.001 inch), enabling tight tolerances. Surface finishes down to Ra 1.6 are often possible.

Achieving this level of precision hinges on the machine’s design and correct setup:

- Precision Components: Quality portable millers incorporate features found in larger machines, such as ground dovetail ways for smooth, accurate movement, precision lead screws1 (often Acme threads with roller bearings), and fine-increment adjustment dials (like 0.001 inch or 0.1 mm) for depth control.

- Rigid Mounting: A stable, secure mount is fundamental to prevent vibration and ensure accuracy. We’ll cover how they mount shortly.

- Controlled Cutting: Consistent feed rates, whether manual or powered, combined with sharp, appropriate tooling (HSS or carbide end mills), lead to accurate dimensions and good surface finishes. Some models explicitly state achieving finishes like Ra1.6, which is suitable for many industrial fits.

- Operator Skill: Proper alignment, careful setup using indicators and levels, and taking appropriate cutting passes are crucial for maximizing the machine’s inherent accuracy.

While perhaps not matching the absolute micron-level precision of a climate-controlled CNC center, these portable units deliver impressive, functional accuracy right where it’s needed, meeting the demands for most industrial keyways, slots, and flats.

What are the main applications of portable keyway milling machines in heavy industry?

Wondering where these portable powerhouses shine? They are far from niche tools. Anywhere large equipment needs modification or repair without being moved is a prime candidate for portable machining.

Their main applications are in on-site maintenance and repair across heavy industries like mining, construction, shipbuilding/repair, power generation, steel mills, pulp & paper, and large equipment manufacturing—essentially, anywhere moving the workpiece is impractical.

Based on my experience and your insights, these machines are indispensable problem-solvers:

- On-Site Maintenance & Repair2: Fixing worn or damaged keyways, cutting new slots, milling flats on shafts, or repairing flange faces without removing the component saves enormous time. This is common in manufacturing plants, processing facilities, and refineries.

- Mining & Construction Equipment3: Repairing keyways or modifying shafts on excavators, crushers, conveyors, shovels, and drills directly in the field minimizes costly downtime for critical machinery.

- Shipbuilding & Repair: Indispensable for working on propeller shafts, rudder stocks, engine components, winch drums, and deck machinery within the confines of a vessel or shipyard.

- Power Generation4: Essential for maintaining turbines (steam, gas, hydro), generators, large pumps, and associated equipment, often involving work on massive rotor shafts or casings during planned outages or emergency repairs.

- Heavy Machinery Manufacturing/Modification: Used for final fitting, modifications after assembly, or custom work on large components like press frames, gearboxes, or machine bases.

Here’s a quick look at where they fit:

| Industry | Common Tasks | Key Benefit |

|---|---|---|

| Mining/Construction | Repairing shafts on crushers, excavators, conveyors | Reduced field downtime, cost savings |

| Shipbuilding/Offshore | Propeller/rudder shafts, engine parts, couplings, winch drums | Avoided dry-docking/transport, faster repairs |

| Power Generation | Turbine/generator rotors, pump shafts, couplings | Faster outage repairs, reduced lost revenue |

| Manufacturing/Industrial | Repairing fixed machinery shafts, post-assembly modifications | Minimized production halt, flexibility |

| Pulp & Paper / Steel Mills | Roll journals, gearbox shafts, conveyor drives | Reduced downtime for critical process lines |

Essentially, if it’s big, heavy, fixed, or critical, and needs a keyway, slot, or flat, portable milling is often the smartest approach.

How is the keyway milling machine mounted on a workpiece?

So, how does this compact machine grip onto a giant, possibly greasy, shaft or a flat metal surface securely enough to mill accurately? Stability is everything. A loose machine means chatter, poor finish, and incorrect dimensions.

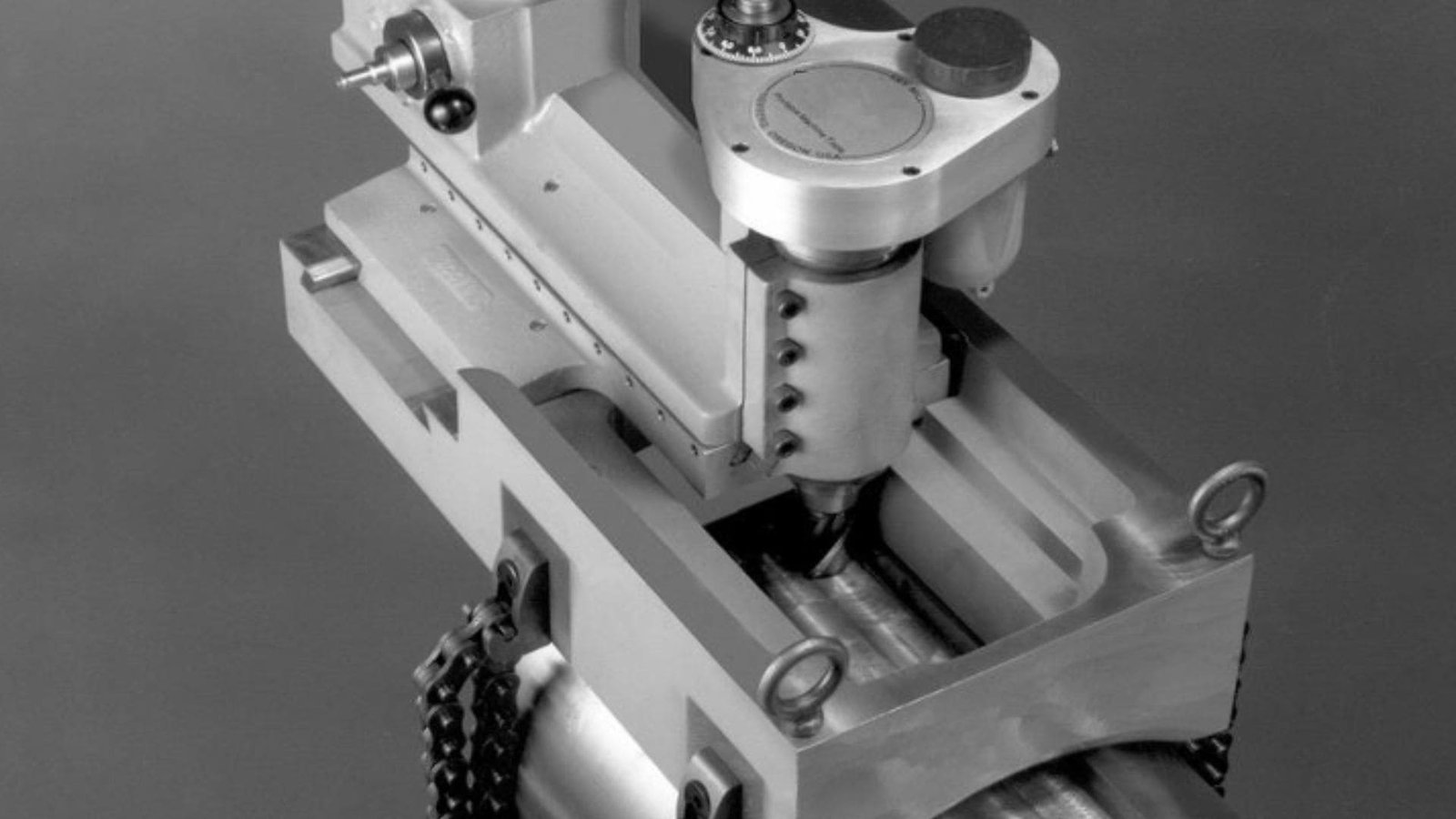

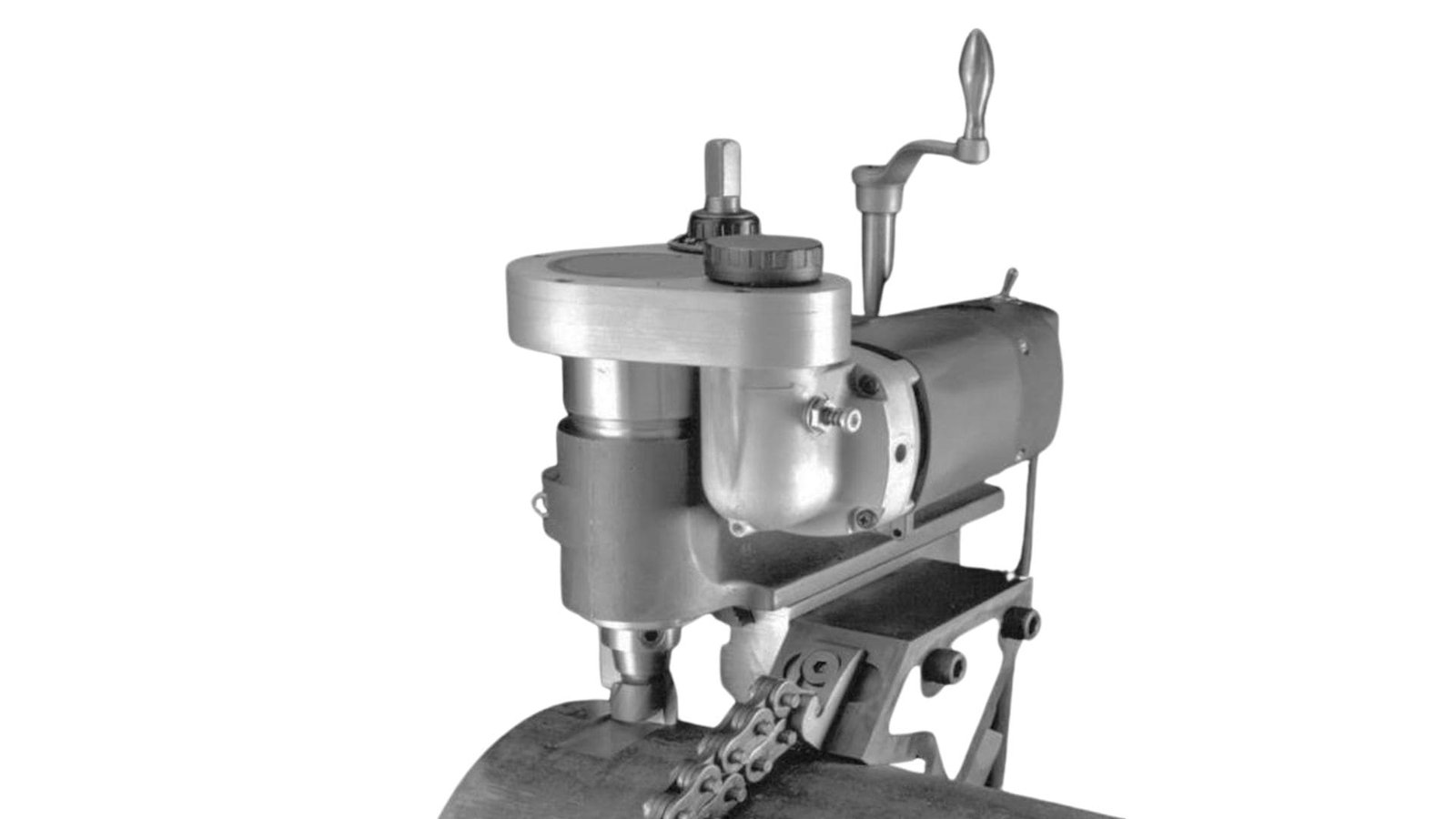

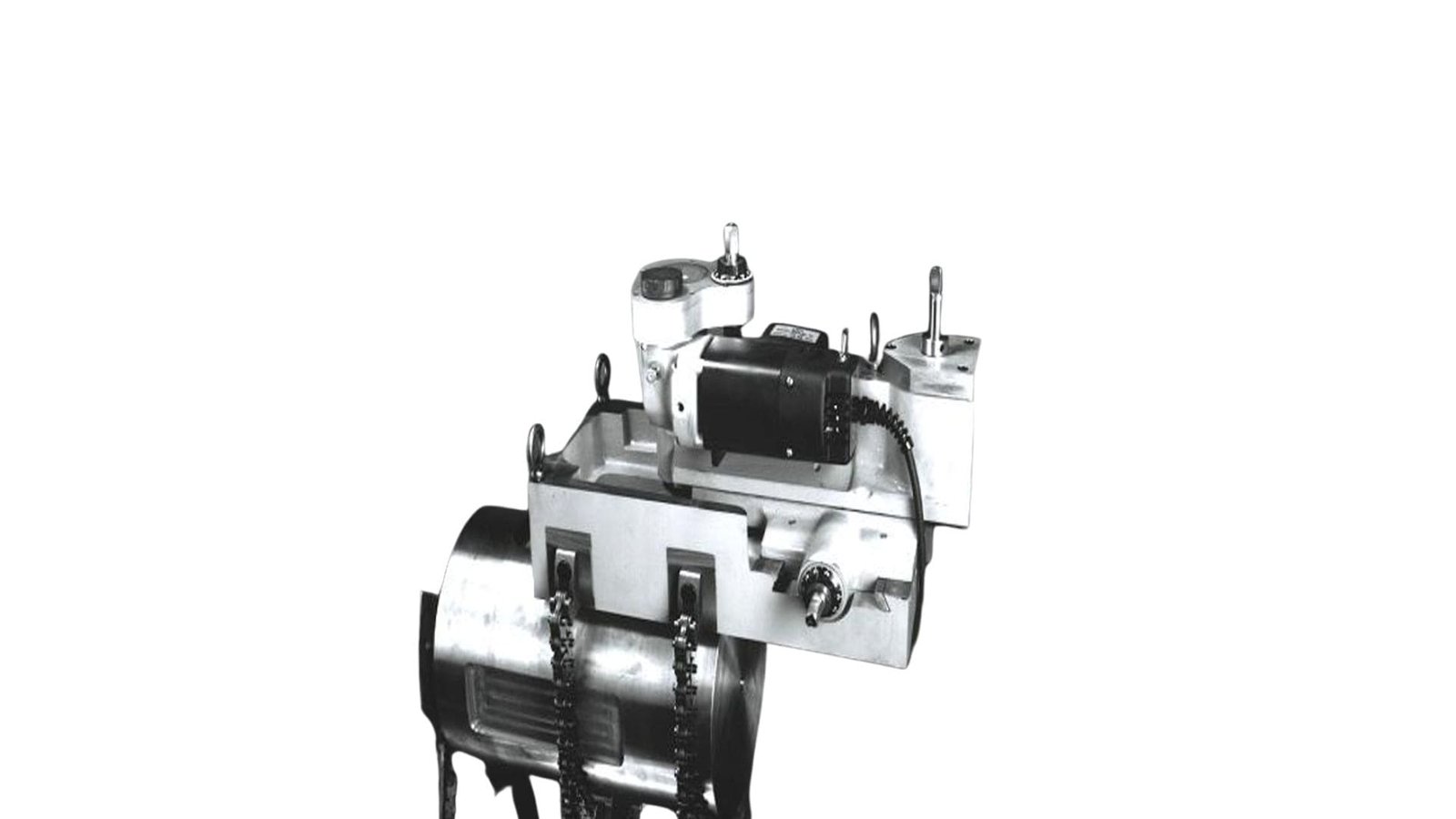

Mounting typically uses robust clamping systems like self-centering V-bases with chain or bar clamps for shafts, direct bolting to flanges, or powerful magnetic bases for flat ferrous surfaces. Some designs need very little shaft length (e.g., 1.5 inches) to mount.

Getting the machine solidly mounted and perfectly aligned is crucial. Here are the common methods:

- V-Base Clamping (Shafts)5: Many designs feature a V-shaped base that naturally centers the machine on the shaft. Clamping is often done with simple bar clamps for smaller diameters or robust roller chain clamps that wrap around larger shafts (up to 24 inches or more), pulling the V-base firmly onto the shaft. Some only need a short section of exposed shaft (like 1.5 inches) to grab onto.

- Magnetic Bases: For working on flat, thick steel or iron surfaces (like machine beds or structural elements), powerful switchable magnetic bases offer a quick and secure mounting option without needing clamps or bolts. Surface cleanliness is important for maximum holding force.

- Direct Bolting: If working on a flange face or a surface with suitable bolt holes, the machine base can sometimes be bolted directly down for maximum rigidity.

- Flat Surface Clamping: Adapters or the base design itself may allow clamping directly onto flat surfaces or edges.

- Alignment is Key: Before cutting, operators use dial indicators, precision levels, and squares to ensure the machine’s feed axis is perfectly parallel to the shaft centerline or aligned correctly with the reference surface.

And don’t forget that sealed lubrication system6 mentioned in your insights – it allows these machines to be mounted and operated reliably in any orientation: horizontal, vertical, or even upside down, greatly increasing accessibility.

How can portable keyway milling machines reduce downtime and save maintenance costs?

We all know downtime bleeds money through lost production, idle labor, and potential contract penalties. So, how does bringing a relatively small machine to a big job actually impact the bottom line compared to traditional methods?

By machining directly on-site, portable machines drastically cut downtime—eliminating disassembly, transport, workshop queues, and reassembly—saving significant labor, logistics, and lost production costs. The investment can pay for itself quickly.

Let’s break down the cost savings:

- Eliminates Major Labor: Avoids the hours or days of millwright/technician time needed for disassembly and reassembly of large equipment.

- Zero Transport Costs: Saves rigging, crane hire, specialized transport, and associated logistics expenses for moving heavy parts.

- Massive Reduction in Lost Production7: This is often the biggest saving. Turning weeks of downtime into hours or days keeps production lines running, generators generating, or ships sailing much sooner. Setup can be fast, and cutting a keyway might take minutes, not days waiting for a shop.

- Faster Overall Turnaround8: On-site work starts immediately and finishes faster. No waiting periods.

- Reduced Risk: Minimizes the risk of collateral damage during transport or encountering issues during reassembly.

- Cost-Effective Investment: The purchase price of a portable keyway miller can often be comparable to the total cost of one major off-site repair. After that single use, subsequent on-site jobs represent significant savings.

- Flexibility: Available power options (electric, pneumatic, hydraulic) allow use in various industrial environments.

Think about a large press gear needing a keyway repair. The cost of removing it, shipping it, shop time, return shipping, and re-installing it could easily exceed the cost of buying a portable keyway miller, which can then be used for future repairs across the plant, generating ongoing savings.

Conclusion

Portable keyway milling machines are essential problem-solvers for heavy industry, enabling precise machining of keyways, slots, and flats directly on large or fixed workpieces. Their ability to deliver accuracy on-site dramatically cuts downtime and costs, making them a highly valuable maintenance and repair tool.

-

Understanding precision lead screws can enhance your knowledge of milling machine accuracy and performance. ↩

-

Explore this link to understand how On-Site Maintenance & Repair can save time and costs in manufacturing processes. ↩

-

Discover insights on how timely repairs in the field can significantly reduce downtime and enhance productivity in mining and construction. ↩

-

Learn about the critical maintenance practices in Power Generation that help prevent revenue loss during outages and repairs. ↩

-

Explore this link to understand the mechanics and benefits of V-Base Clamping for effective machine alignment. ↩

-

Learn about sealed lubrication systems and how they enhance machine reliability in various orientations. ↩

-

Learn about the importance of minimizing downtime and its effects on overall production efficiency. ↩

-

Discover the benefits of quick maintenance turnaround and how it can enhance operational efficiency. ↩