Your CNC Whirling Solution

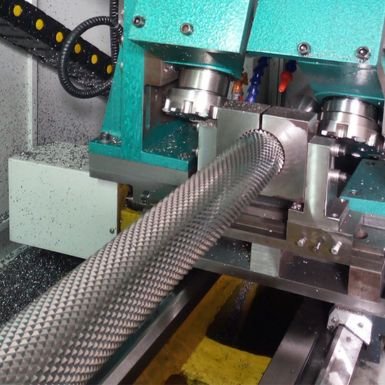

J&M is a metal-working machine tools manufacturer offering powerful CNC whirling solutions. CNC whirling machines excel in threading long rods, offering single-pass precision, superior surface finish, efficient chip control, and extended tool life, enhancing productivity and cost-effectiveness.

What We Provide

Dedicated for Screw Pump Rotors

Dedicated for Extruder Screw Elements

Dedicated for Petroleum Grooved Drill Pipes

Dedicated for Steel Mill Conveyor Rollers

Contact Us for

More Tailored

Options

Dedicated for Particleboard Paving Machine Diamond Rollers

Applications

Oil Drilling

Petroleum Grooved Drill Pipe

Downhole Motor Screw

Sucker Rod

Plastics and Rubber

Extruder Screw Elements

Internal Mixer Rotors

Pelletizer Rotor

General Manufacturing

Trapezoidal Screws

Compressor Screws

Racks and Spline Shafts

Want to manufacture similar products ? Let's discuss your needs !

Key Benefits

Precision and Accuracy

Multi-edge cutting combined with advanced tooling ensures extremely tight tolerances and exceptional surface finishes. This process is crucial for producing precision components that meet strict quality specifications and dimensional requirements.

Increased Efficiency

Single-pass threading produces short, easily evacuated chips, significantly boosting output. This efficient process minimizes cycle times, making it ideal for high-volume manufacturing and contributing to reduced overall production time.

Broad Applicability

Thread whirling excels with long, slender workpieces, deep threads, and large pitches. It is also highly effective for machining difficult materials like hardened steels and high-temperature alloys, ensuring wide-ranging utility.

Enhanced Stability

The tool's close proximity to the machine spindle minimizes vibration, providing superior stability for machining long workpieces and hard materials. This design also significantly extends tool life and reduces operational wear.

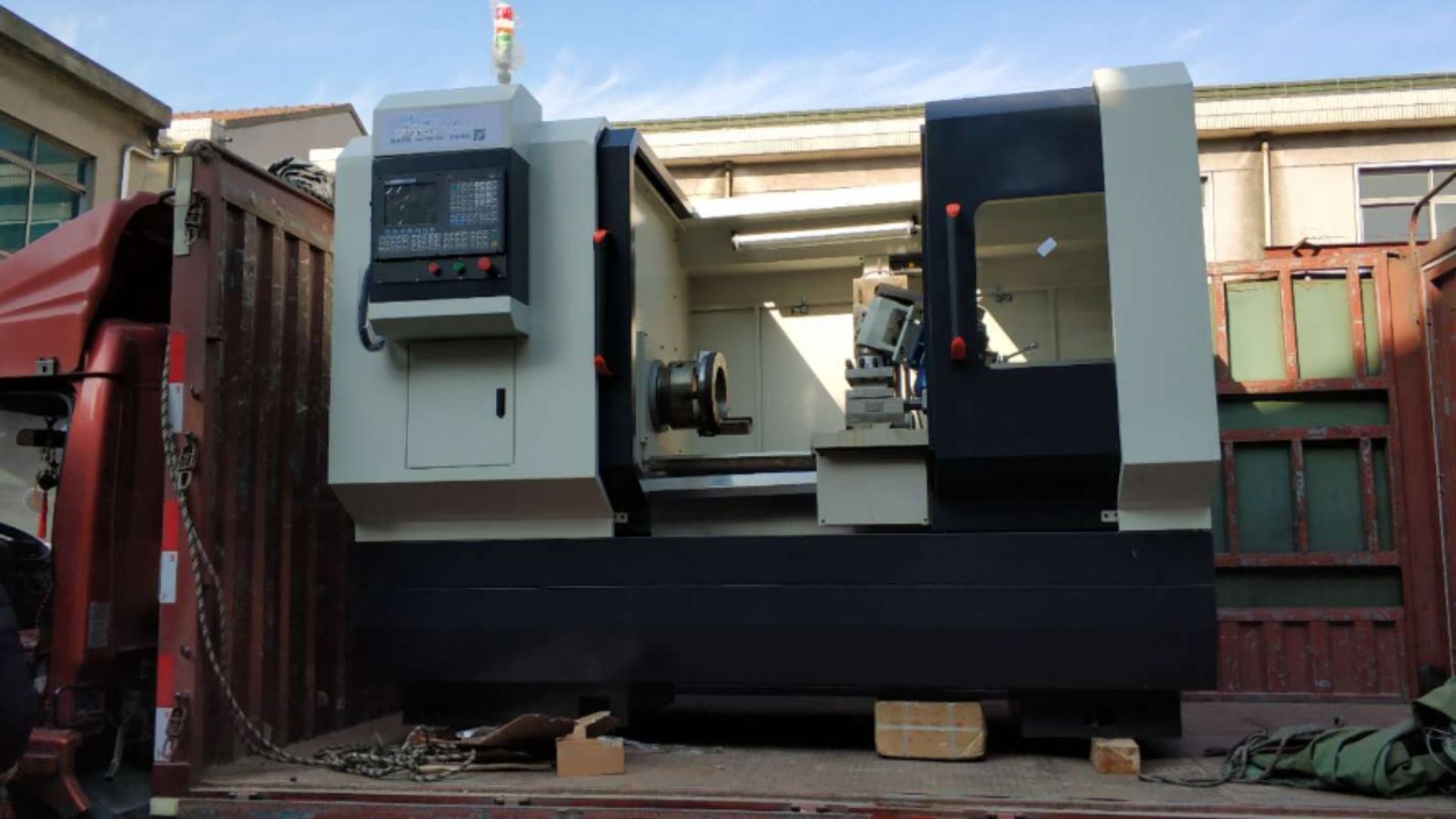

CNC Whirling Machine Shipping & Delivery

Witness our commitment to customer satisfaction as we prepare and dispatch our high-quality CNC Whirling Machines worldwide. Each machine undergoes rigorous final inspection and professional packaging to ensure it arrives safely and efficiently at its destination, ready to boost your production capabilities.

Frequently Asked Questions

Here are some questions frequently asked. If you still have questions. Contact us, and we'll gladly provide the answers you're looking for!

Our equipment supports a wide range of materials, including aluminum, steel, stainless steel, and other metals. For specific requirements, please contact us for the best solution!

Our equipment is ideal for various industrial applications, such as automotive parts, aerospace components, and electronic parts. If you need specific recommendations, we can suggest the most suitable model for your needs!

We provide a 24-month warranty for all our equipment, with detailed terms and optional extended warranty services available.

Hear from Clients

Testimonials

"Our previous diamond roller milling, using modified gantry machine heads, was inefficient and resulted in severe burrs. JM's CNC whirling machine has revolutionized this, delivering a burr-free surface and automatic indexing. This enables one person to operate 3-5 machines, greatly increasing production efficiency and reducing labor costs."

"We previously struggled with the time-consuming and laborious machining of internal and external swing cylinder teeth on machining centers. JM's CNC whirling machine provided a significant breakthrough, greatly enhancing both efficiency and surface finish."

"Facing rising labor costs and inefficient manual turning of hard screw elements, our extruder industry needed a solution. JM's CNC whirling machine has delivered, rapidly cutting and forming in a single pass. This innovation has boosted our production efficiency to equal four previous workers, truly a breath of fresh air for our business."

"For a critical oil industry workpiece, we encountered major difficulties with the internal threads – specifically, a large hole and high helix angle – that no other cyclone milling manufacturer could address. JM, however, immediately confirmed a solution. Their expertise has been instrumental in advancing our oil exploration capabilities."

Ready to work with us? Contact now to get started!

Get your quote TODAY!

Office Location

2406C, Kingkey Times Center,

Huangge Road,Longgang District,

Shenzhen, China