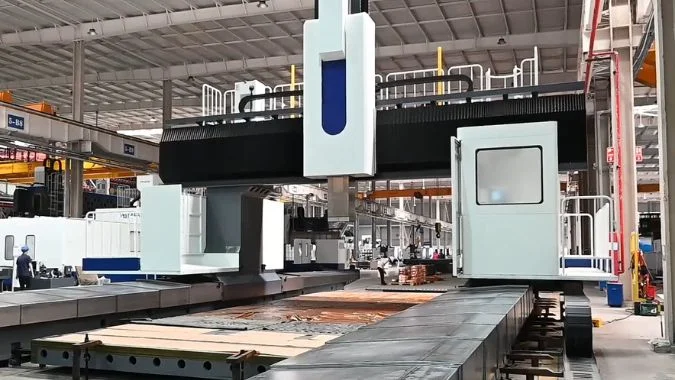

How to Calibrate the Geometric Accuracy of a Five-Axis Gantry Machining Center?

Your expensive workpieces are being scrapped because your five-axis gantry machine lost its precision. Ignoring minor geometric errors leads to costly rework and production delays.

Calibrating a five-axis GMC involves using laser interferometers and ball bars to measure parallelism, perpendicularity, and positioning. You must systematically adjust guide rails, support structures, and servo parameters to ensure all axes move precisely within strict tolerances, restoring the machine to factory specifications.

Many operators blame the cutting tools or the programming when the machine geometry is actually the problem. You need to understand the calibration process to maintain high quality.

Why Must Geometric Accuracy Issues Be Identified and Addressed in Five-Axis GMC?

You ignore small vibrations until the spindle crashes or the surface finish looks terrible.

Geometric accuracy defines the machine’s ability to hold parallelism, perpendicularity, and positioning. Failing to address errors caused by thermal deformation, stress relaxation, or mechanical wear leads to permanent equipment damage, abnormal component wear, and rejected parts.

We need to look at the machine as a solid body that changes shape. A machine that was perfect a year ago now might cut ovals instead of circles.

The Core Accuracy Elements

A five-axis gantry machine1 relies on four specific physical traits. First is parallelism. The tracks must run exactly alongside each other. Second is perpendicularity. The X, Y, and Z axes must form perfect 90-degree angles. Third is positioning accuracy. If you tell the machine to go 500mm, it must go exactly 500mm. Fourth is repeatability. The machine must hit that same spot a thousand times in a row.

Sources of Deviation

These errors do not happen by magic. They come from three main enemies.

- Thermal Deformation2: Metal expands when it gets hot. During long shifts, friction heats up the screws and rails. The dimensions change slightly.

- Stress Relaxation: A heavy gantry is under constant stress. Over time, or after heavy vibration, the metal internal structure relaxes. This twists the geometry.

- Mechanical Wear: Every time the machine moves, the rails and ball screws wear down. This creates "slop" or backlash that kills precision.

If you ignore these, the machine fights itself. The motors work harder. The rails grind. You lose accuracy today, but you destroy the machine tomorrow.

| Error Type | Consequence | Primary Cause |

|---|---|---|

| Parallelism Loss | Binding rails, uneven wear | Foundation settling, Stress relaxation |

| Perpendicularity Loss | Square parts become rhomboid | Collision, Loose assembly |

| Positioning Error | Dimensions are wrong | Screw wear, Thermal expansion |

| Repeatability Loss | Inconsistent batch quality | Backlash, Servo tuning issues |

How We Perform Geometric Accuracy Calibration on a Five-Axis GMC in Practice?

You cannot just guess and tighten a bolt to fix a complex five-axis machine.

The process requires a strict sequence: preliminary inspection with laser interferometers, error source analysis, and then mechanical adjustments. You must calibrate parallelism and perpendicularity first, followed by positioning accuracy and spindle alignment to ensure the entire kinematic chain is correct.

We follow a specific order. You cannot tune the motors if the physical rails are crooked. It is like trying to drive a car straight when the frame is bent.

Step 1: Inspection and Analysis

We start by measuring everything before we touch a wrench. We use a laser interferometer3 and a ball bar instrument. We run the machine through its full travel. We record the errors. This tells us if the problem is a loose screw, a worn rail, or a tilted spindle.

Step 2: Mechanical Geometry Correction

We fix the physical alignment first.

- Parallelism: We use the laser data to adjust the guide rails. We loosen the bolts and tap the rail until it is perfectly straight.

- Perpendicularity: We use a granite square or laser level. If the X-axis is not 90 degrees to the Y-axis, we adjust the gantry support structure. We physically move the heavy iron until it is square.

Step 3: Positioning and Spindle Tuning

Once the machine is physically straight, we fix the motion. We use the laser to measure the exact position of the axis. If the display says 100mm but the laser says 99.995mm, we update the "pitch error compensation" in the CNC controller4. Finally, we check the spindle. A tilted spindle makes bad surface finishes. We use a test bar and dial indicators to sweep the table. If it is off, we shim the spindle bearings or adjust the headstock.

What Measurement Data Are Required to Ensure Effective Geometric Accuracy Calibration?

You have the tools, but you do not know the numbers to hit.

Effective calibration relies on meeting specific ISO standards. You need to achieve parallelism within 0.01mm/m, perpendicularity within 5μm/300mm, and positioning accuracy within ±0.005mm to guarantee high-precision machining results.

Data is the only thing that matters. "It looks straight" is not good enough for precision manufacturing. You need to know the specific tolerances we aim for.

Defining the Standards

We generally refer to international standards like ISO 230-1:20125. However, the specific numbers depend on what you are making. For high-precision aerospace parts, the requirements are tighter than for general roughing.

Key Data Targets

- Parallelism: We look for an error of less than 0.01mm for every meter of travel. If the gantry travels 10 meters, we allow very little deviation. This prevents the motors from fighting each other.

- Perpendicularity: This is the most critical for 5-axis work. We need the axes to be square within 5 microns (0.005mm) over a 300mm distance. Any more than that, and your complex 5-axis moves will not blend correctly.

- Positioning Accuracy6: For a high-end machine, we target ±0.005mm total error. This ensures that the hole you drill is exactly where the drawing says it is.

- Repeatability: This tests the machine’s stability. We want to see the machine return to the same spot within ±0.003mm. This proves the mechanical system is tight and the servo loops are tuned correctly.

| Metric | Standard Tolerance | Why it Matters |

|---|---|---|

| Parallelism | 0.01mm / meter | Prevents rail binding and motor overload |

| Perpendicularity | 5μm / 300mm | Ensures accurate 3D geometry |

| Positioning | ±0.005mm | Critical for dimensional tolerance |

| Repeatability | ±0.003mm | Essential for mass production consistency |

What Key Factors and Precautions Should Be Considered During Geometric Accuracy Calibration?

You follow the steps but still get bad results because the environment is wrong.

Successful calibration requires a stable environment with controlled temperature and humidity to prevent thermal expansion. You must use high-precision tools like ball bar instruments and establish a regular maintenance schedule to prevent accuracy drift over time.

I have seen calibration jobs fail because someone opened the loading bay door. A blast of hot air changed the machine size by 20 microns. You must respect the environment.

Environmental Control

Temperature is the biggest variable.7 Metal grows when it gets warm. Ideally, you calibrate in a constant temperature workshop (20°C). If you do not have AC, you must calibrate after the machine has "soaked" or cooled down, usually early in the morning. You also need to watch humidity, as it affects laser measurement beams.

Tooling Integrity

Your calibration is only as good as your tools. We use Renishaw lasers and ball bars. These tools must be calibrated themselves. If your square is not square, your machine will not be square. You must mount the equipment on stable bases to avoid vibration during the test.

The Maintenance Cycle

Calibration is not a one-time event. It is a cycle. We recommend checking geometry every 6 to 12 months, or after any crash. You should create a logbook. Track the errors over time. If you see the X-axis getting worse every month, you know a bearing is failing before it breaks completely. This proactive approach saves you from unexpected downtime.

Conclusion

Geometric accuracy is the heart of your five-axis machine. Regular calibration using data and proper tools ensures your production stays profitable and your machine lasts longer.

-

Understanding the five-axis gantry machine is crucial for optimizing precision in manufacturing processes. ↩

-

Exploring thermal deformation will help you grasp its impact on machine accuracy and longevity. ↩

-

Understanding laser interferometers can enhance your knowledge of precision measurement in machine alignment. ↩

-

Exploring CNC controllers will deepen your insight into automated machining and precision adjustments. ↩

-

Understanding ISO 230-1:2012 is crucial for ensuring high standards in precision manufacturing, especially for aerospace parts. ↩

-

Exploring positioning accuracy will help you grasp its significance in achieving exact specifications in manufacturing processes. ↩

-

Understanding temperature’s role in calibration can help you maintain precision and avoid costly errors. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.