How to Choose Between a Mechanical Spindle and an Electric Spindle in a VMC?

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs

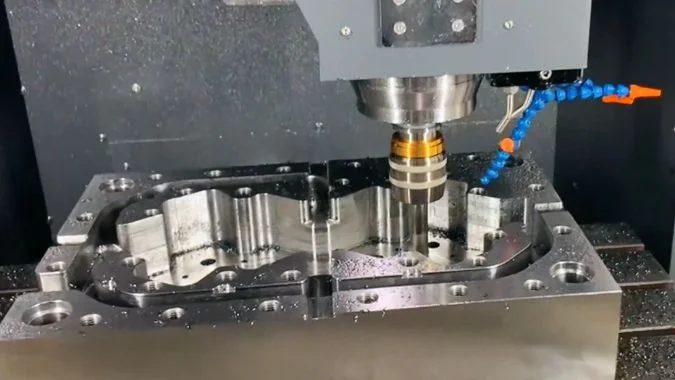

You’re speccing out a new VMC, and the options for the spindle are confusing. Picking the wrong one means you could end up with a machine that stalls on heavy cuts or can’t produce the fine finish you need.

Choose a mechanical spindle for heavy-duty cutting in tough materials where high torque is essential. Select an electric spindle for high-speed machining, superior accuracy, and excellent surface finishes, especially in lighter materials or for precision work.

It’s one of the most critical decisions because the spindle is the heart of the machine. It dictates your VMC’s entire personality—is it a powerful workhorse for roughing steel, or is it a high-speed artist for finishing aluminum molds? The right choice isn’t about which is "better" overall, but which is perfectly suited to the work you do every day. Getting this right from the start will define your shop’s capabilities for years to come.

What are the Fundamental Differences Between a Mechanical and an Electric Spindle?

You’re looking at the specs, and terms like "belt-driven," "gear-driven," and "built-in motor" are thrown around. You need to know what this actually means for how the machine works.

A mechanical spindle uses an external motor connected by a transmission, like belts or gears, to turn the spindle. An electric spindle has the motor built directly into the spindle housing, eliminating the need for any transmission components.

Think of it like this: a mechanical spindle is like a classic car engine connected to the wheels through a transmission. An electric spindle1 is like the motor inside a modern electric vehicle’s wheel hub—it’s all one compact, integrated unit. This "zero transmission" design is the key difference. Electric spindles use a frequency converter for stepless speed adjustment, offering incredible versatility. Mechanical systems are the traditional, proven method that uses the leverage of gears and belts. This single design choice affects everything from power and speed to accuracy and maintenance.

A Tale of Two Designs

The two approaches have completely different strengths. The mechanical design2 is simpler to maintain; if a belt wears out, you replace the belt. The electric spindle is a complex, integrated unit that requires specialists for repair, often at a higher cost. However, by removing transmission parts, the electric spindle becomes more efficient, compact, and capable of incredible speeds.

| Feature | Mechanical Spindle (Belt/Gear) | Electric Spindle (Built-in) |

|---|---|---|

| Drive System | External motor with belt or gear transmission. | Integrated motor, direct drive. |

| Speed Range | Lower (typically 6,000–12,000 RPM). | Very high (15,000 to 24,000+ RPM), stepless adjustment. |

| Torque | Superior torque, especially at low RPMs. | Lower standard torque; high-torque models are a costly upgrade. |

| Vibration | Higher due to belts/gears and external motor. | Very low, resulting in smoother operation. |

| Maintenance | Simpler and often cheaper to repair individual parts. | More complex and expensive to service; requires specialists. |

| Applications | Heavy cutting in hard materials like steel and cast iron. | High-speed finishing, precision milling, complex geometries. |

What Spindle Type Delivers Better Torque for Heavy-Duty Cutting?

You need to hog out large amounts of tough material like stainless steel, Inconel, or cast iron. You’re worried about the cutter chattering, or even worse, the spindle stalling in the middle of a cut.

A mechanical spindle, especially a gear-driven one, delivers significantly better torque for heavy-duty cutting. The gearbox acts like the low gears in a truck, providing the raw power needed to machine hard materials at lower speeds.

When it comes to brute force, mechanical spindles3 are the clear winner. The transmission system allows the motor to use leverage to generate massive torque. This is essential for large-diameter tools, deep cuts, and materials that fight back. I’ve seen shops try to rough hard steel with a standard electric spindle, and it’s a constant battle. They simply lack the low-end grunt needed for serious material removal. While high-torque electric spindles exist, they come at a premium price. For most shops focused on heavy cutting, a mechanical spindle is the most reliable and cost-effective choice.

Power Where You Need It

The key is understanding the relationship between speed and torque. Electric spindles are designed for high RPMs but their torque is often lower. They are fantastic for high-speed machining where you take lighter cuts very quickly in materials like aluminum. A mechanical spindle is the opposite. It is designed to deliver consistent, high torque4 across its lower RPM range (typically up to 10,000 RPM). This makes it the ideal choice for any application that involves removing a lot of material quickly, especially in ferrous metals and tough alloys.

How Does Spindle Choice Impact the Final Accuracy and Surface Finish of a Part?

Your parts require tight tolerances and a mirror-like surface finish. You are chasing down tiny imperfections and know that vibration is your number one enemy, but you’re not sure where it’s coming from.

An electric spindle provides significantly better accuracy and surface finish. Its integrated, balanced design and lack of transmission parts eliminate the vibration and errors that cause chatter, leading to a much smoother cut.

Every machinist knows the sound of chatter. A major source of that vibration comes from the spindle drive system. In a mechanical spindle, you have belts that can flap and gears that create tiny vibrations. An electric spindle, however, is a single, precision-balanced rotating assembly. With no external transmission parts, it runs incredibly smoothly. This lack of vibration allows the cutting edge to make a cleaner pass, directly improving surface finish and overall part accuracy. For precision work, you want a spindle with minimal runout—the deviation from its rotational axis—to ensure the tool is cutting exactly where it should be.

The Pursuit of Precision

The benefits go beyond just surface finish. The transmission errors5 in a mechanical system, like gear backlash, can introduce small inaccuracies into your tool path. An electric spindle’s "zero transmission" design results in higher positioning accuracy, which is critical for complex 5-axis work or fine mold details. Advanced features like ceramic bearings also help manage thermal expansion, keeping the spindle stable and accurate even during long runs. If your work is judged by microns and surface quality, an electric spindle is a necessity.

Can the Spindle Choice Affect the Lifespan of Your Cutting Tools?

You feel like you are burning through expensive end mills faster than you should be. You’re constantly fighting tool wear and breakage, which hurts both your bottom line and your production schedule.

Yes, the spindle choice has a direct impact on tool life. The low vibration of an electric spindle reduces tool fatigue in light cuts, while the high torque of a mechanical spindle prevents strain on tools during heavy cuts.

It’s a balancing act. An electric spindle’s smooth operation significantly reduces the micro-vibrations that cause fatigue and chipping on a tool’s cutting edge. This is especially true when using small-diameter tools for high-speed finishing. The reduced friction and heat can prolong the life of modern coated tools. However, if you use an electric spindle for a heavy cut it wasn’t designed for, its lower torque can lead to tool deflection and chatter, which will destroy a tool in seconds.

Matching the Tool to the Task

A mechanical spindle protects tools in a different way. Its high torque and robust design provide the stability needed for deep cuts in hard materials. This prevents the tool from getting bogged down or chattering under a heavy load, which is a common cause of breakage. The spindle is built to absorb those cutting forces, saving your tool from excessive strain. The key is to match the spindle to the application. Using a mechanical spindle for heavy roughing and an electric spindle for high-speed finishing will not only make your machine more productive but will also optimize the life of your cutting tools.

Conclusion

Choose a mechanical spindle for torque-driven, heavy cutting in tough materials. Opt for an electric spindle when your priorities are high speed, precision accuracy, and a flawless surface finish.

-

Explore the benefits of electric spindles, including efficiency and speed, to understand their impact on modern manufacturing. ↩

-

Learn about the simplicity and reliability of mechanical designs, which are crucial for traditional manufacturing processes. ↩

-

Explore the benefits of mechanical spindles for heavy cutting and material removal, and see why they’re preferred in many shops. ↩

-

Understanding high torque’s role in machining can help you choose the right tools for efficient material removal. ↩

-

Learn how transmission errors can impact your machining processes and how to mitigate them. ↩