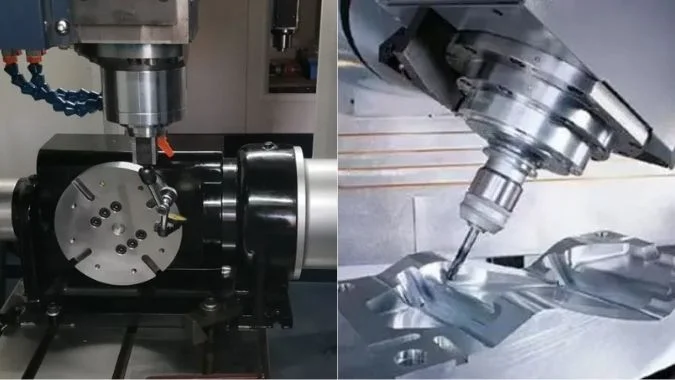

How to Choose Between a Trunnion-Type and Swivel-Head 5-Axis Machining Center?

You are ready to invest in a 5-axis machine, but the choice between a trunnion and a swivel-head is confusing. Making the wrong decision can leave you with a machine that can’t handle your largest parts or can’t reach the features on your most complex ones.

Choose a trunnion-style machine for small, complex parts that require excellent undercutting and tool access, especially in hard materials. Select a swivel-head machine for machining very large and heavy workpieces where the table must remain flat and stationary to support the weight.

This is a fundamental choice that defines what kind of work your shop will excel at for the next decade. Some shops buy a beautiful trunnion machine only to realize their most profitable jobs are too heavy for the table to lift. Some shops with swivel-head machines struggle with tiny, intricate medical parts because they couldn’t get a short, stubby tool into the right position. The secret is to stop looking at the machine first and start by looking at your parts. The part always tells you which machine it wants to be made on.

Why is a Swivel-Head 5-Axis Machining Center Generally Better for Large and Heavy Workpieces?

You have a massive die casting or a huge aerospace structural frame to machine. You’re worried that a standard 5-axis machine won’t be able to handle the sheer weight without losing accuracy.

A swivel-head is better because the workpiece is clamped onto a large, stationary table that only moves in X and Y. All the tilting and rotating happens in the head, so there are almost no practical limits on part weight and size.

The core advantage of a swivel-head machine1 is its structure. Think of the worktable as a simple, incredibly strong foundation. Its only job is to move the part left-to-right and front-to-back. It never has to lift or tilt the part. The spindle head, which is much lighter than your workpiece, handles all the complex A and C axis rotations. This design completely separates the part’s weight from the rotary axes. As a result, you can machine super-large components over 2,000 mm found in the aerospace, energy, and mold-making industries without worrying about overloading the machine’s tilting mechanism.

Work Envelope and Weight Capacity

The design of a swivel-head machine offers two major benefits for large parts: a consistent work envelope2 and massive weight capacity. A trunnion machine’s work envelope can shrink dramatically as the table tilts a large part towards the machine’s column, creating potential interference. A swivel-head machine doesn’t have this problem. The work envelope is largely unaffected by the tool’s orientation. Furthermore, the weight limitations are significantly higher. While a trunnion table might be limited to around 500 kg, a comparable swivel-head machine’s table could easily support several tons. This makes it the default configuration for industries that need to machine parts you can’t lift by hand.

How Does a Trunnion-Style 5-Axis Machining Center Provide Better Undercutting and Tool Access on Small, Complex Parts?

You machine small, intricate parts like medical implants or impellers. You constantly struggle to reach tight features and deep pockets without using dangerously long and flexible tools.

A trunnion-style machine provides better access by tilting the workpiece itself towards the tool. This movement opens up the part, allowing you to use shorter, more rigid tools to easily reach undercuts and side features.

Imagine holding a small, complex object in your hand. To inspect a feature on the underside, you don’t crane your neck; you simply tilt the object. A trunnion machine works the exact same way. The A and C axes are in the table, which cradles and tilts the part, often through a huge range like -30° to +110°. This action effectively moves the part out of its own way. As the part tilts, it creates a large clearance area around the tool, making it incredibly easy to access features that would be impossible to reach on a swivel-head machine without a very long tool. This is why trunnion machines3 dominate industries like medical and aerospace, where small, high-value parts are the norm.

The Advantage of Tilting the Part

When the machine tilts the workpiece, you gain a significant advantage in cutting dynamics4. You can use the shortest, most rigid tool possible for the job. A shorter tool deflects less, vibrates less, and allows for much more aggressive and accurate cutting. This leads to better surface finishes, longer tool life, and shorter cycle times. On a swivel-head machine, the part stays flat, so the head has to tilt to reach a side feature. This often forces you to use a longer tool holder and tool to avoid colliding the spindle head with the workpiece or fixture. That extra length introduces flex and limits your cutting performance, something you can’t afford on complex, high-precision parts.

Which Design Offers Greater Rigidity and Stability at the Tool Tip?

You need to machine tough materials like steel or titanium. You know that any lack of rigidity will result in chatter, poor tool life, and inaccurate parts. You need to know which design is fundamentally more stable.

A trunnion-style machine often offers greater rigidity at the tool tip because its design allows for the use of shorter tools. Stability comes from keeping the distance from the spindle face to the cutting edge as short as possible.

This might seem counter-intuitive at first. The swivel-head machine has a simpler head and a solid table, which sounds more rigid. However, true cutting rigidity5 is determined at the point of contact: the tool tip. As we discussed, a trunnion machine tilts the part, creating clearance that allows you to use very short tools. A tool that is twice as long is many times less rigid. By enabling the use of shorter tools, the trunnion design provides a more stable cutting condition. This is why trunnion machines6 are often preferred for machining hard materials and performing deep cutting operations where tool pressure is high.

Matching Structure to Material

The overall machine construction also plays a role. Trunnion machines, built to handle the dynamic forces of a moving table and aggressive cutting, are often very robust. The fixed spindle is a simple, heavy-duty unit. A swivel-head’s articulating spindle has more moving parts and joints in its assembly, which can be a source of potential vibration. This results in a difference in cutting approach. A trunnion machine is generally better suited for heavy cuts in hard materials like steel, while the lighter cutting forces of a swivel-head machine make it ideal for high-speed finishing on softer materials like aluminum.

What Final Checklist Should You Use to Match Your Parts to the Right 5-Axis Configuration?

You understand the theories, but now you need to make a real-world decision for your shop floor. You need a simple checklist to look at your parts and confidently choose the right machine.

Analyze your parts based on their size, weight, complexity, and material. The answers will point directly to the correct machine configuration, ensuring your investment matches your work perfectly.

Making the right choice is about asking the right questions. Don’t start with the machine catalog. Start with the parts you are making today and the parts you want to make tomorrow. Go through your top 10 most profitable or most challenging jobs and apply this checklist. The pattern that emerges will make your decision clear. I’ve used this method with clients for years, and it removes the guesswork. It ensures the machine you buy is a solution to your problems, not the cause of new ones.

Your 5-Axis Decision Checklist

Use this table to evaluate your primary workload. The column with the most checkmarks is likely the right choice for your shop’s future.

| Question | Choose Trunnion-Style If… | Choose Swivel-Head If… |

|---|---|---|

| 1. What is the typical PART WEIGHT7? | Parts are lightweight to medium (under 500 kg). | Parts are consistently heavy (over 500 kg, up to several tons). |

| 2. What is the typical PART SIZE? | Parts are small to medium, generally under 1,000 mm. | Parts are very large, often exceeding 1,000 mm and even 2,000 mm. |

| 3. How COMPLEX8 are the parts? | Parts have deep pockets, many undercuts, and intricate 3D surfaces. | Parts are large frames, plates, or blocks with 5-sided features. |

| 4. What MATERIALS do you cut most? | Hard materials like steel, titanium, and exotic alloys that require deep cuts. | Softer materials like aluminum, or doing light finishing on steel. |

| 5. What is your top priority? | Maximum tool access for undercuts and using short, rigid tools. | Maximum part weight capacity and a large, open work area. |

| 6. What is your production style? | High-volume batches of smaller, similar parts are common. | Low-volume, custom jobs on large, unique components. |

Conclusion

A trunnion-style machine excels with small, complex parts made from hard materials where tool access is critical. A swivel-head machine is the unbeatable choice for massive, heavy workpieces.

-

Explore this link to understand how swivel-head machines enhance efficiency and precision in machining large components. ↩

-

Learn about the significance of work envelope in machining to optimize your processes and avoid potential issues. ↩

-

Explore this link to understand how trunnion machines enhance precision and efficiency in manufacturing, especially for complex parts. ↩

-

Learn about cutting dynamics to discover how they influence tool performance and machining efficiency, crucial for high-precision industries. ↩

-

Understanding cutting rigidity is crucial for optimizing machining processes and tool selection, enhancing overall performance. ↩

-

Explore the benefits of trunnion machines for improved cutting stability and efficiency, especially in hard material machining. ↩

-

Understanding part weight is crucial for selecting the right machine, ensuring efficiency and safety in production. ↩

-

Exploring part complexity helps in choosing the right machining strategy, optimizing production and reducing costs. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.