How to Choose Between Moving and Fixed Beam Gantry Machining Centers?

Choosing the right gantry machine is a massive investment. The wrong choice leads to crippling limitations in either part capacity or precision, a mistake you can’t afford to make.

Choose a fixed beam gantry for high-precision machining like mold finishing, where superior rigidity is key. Opt for a moving beam gantry for flexibility, especially for extra-large and heavy parts like those in shipbuilding, where the workpiece must stay stationary.

A fixed beam gantry is like a granite bridge—incredibly stable, but its height is set. A moving beam gantry is like a versatile crane—it can adjust to an enormous range of work, but that movement introduces complexity. While the fixed beam is often simpler and potentially less expensive upfront, the moving beam’s adaptability can be priceless. Understanding their core mechanical differences is the first step in selecting the machine that will be a long-term asset, not a liability.

What is the Core Mechanical Difference Between a Moving Beam and a Fixed Beam Gantry Design?

The names sound similar, but their mechanics are worlds apart. Misunderstanding this core difference can lead you to buy a machine that is completely mismatched for your type of work.

In a fixed beam design, the horizontal cross-beam is bolted permanently to the columns and the workpiece table moves. In a moving beam design, the workpiece table is stationary and the entire gantry structure moves over the part.

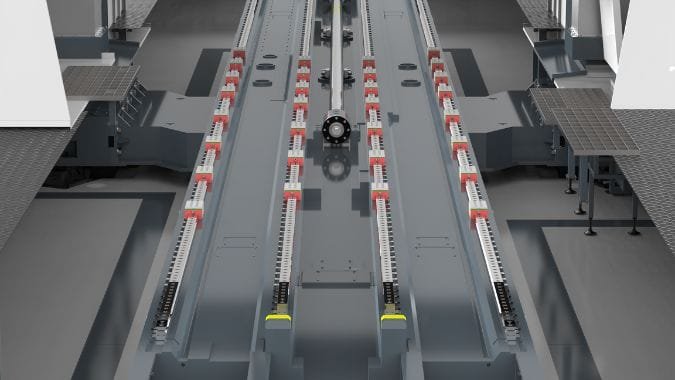

This is the absolute heart of the matter. Imagine a fixed beam gantry1 as a single, solid structure. The beam is locked in place, providing massive, rigid overhead support. The workpiece sits on a table that moves back and forth (X-axis) underneath it. The spindle or ram then moves left-to-right (Y-axis) and up-and-down (Z-axis). Now, picture the moving beam gantry2. The workpiece sits on a fixed table or floor plate. The entire gantry—both columns and the cross-beam—travels along rails in the X-axis. The cross-beam can also move up and down the columns (Z-axis) to adjust for part height. This fundamental difference in what moves versus what stays still dictates everything about the machine’s performance.

Design Philosophy at a Glance

| Feature | Fixed Beam Gantry | Moving Beam Gantry |

|---|---|---|

| Primary Moving Component | The worktable moves along the X-axis. | The entire gantry structure moves along the X-axis. |

| Workpiece Status | Moves with the table. | Stationary on a fixed bed. |

| Mechanical Simplicity | Simpler, fewer moving structural components for the gantry. | More complex, with drive systems for the entire gantry. |

| Primary Advantage | Maximum rigidity and stability. | Maximum flexibility for heavy and long parts. |

Which Structure Offers Higher Machining Accuracy?

Chasing tight tolerances on huge parts is a nightmare. Your machine’s inherent stability is critical, but which design provides the unwavering precision you need for high-value work?

The fixed beam gantry inherently offers higher machining accuracy. Its monolithic, static structure minimizes vibration and eliminates the variables introduced by a moving beam, ensuring superior stability for applications like precision mold finishing.

When it comes to pure accuracy, physics favors the fixed beam design3. Rigidity is the foundation of precision, and a fixed beam gantry is the definition of rigid. Because the beam doesn’t move, it is not subject to the slight shifts that can occur in a moving structure. It is a constant, stable reference point, which is crucial for achieving the micron-level accuracy needed in the mold and die industry. While a moving beam gantry can be very accurate, it has to overcome more challenges. It is better suited for roughing large parts or applications where ultimate precision is secondary to size capacity. That said, modern engineering with advanced damping and compensation systems has narrowed this accuracy gap, but for the absolute most demanding jobs, the fixed beam’s structural integrity gives it a clear advantage.

Factors Affecting Machining Accuracy

- Structural Rigidity: The fixed beam’s simpler, massive structure naturally dampens vibration more effectively, which is key to achieving fine surface finishes.

- Dynamic Errors: A moving beam gantry has more potential for dynamic errors or vibrations caused by the movement of the entire heavy gantry assembly.

- Application Sweet Spot: A fixed beam excels at high-precision finishing. A moving beam excels at heavy roughing and machining massive parts where some precision can be traded for capacity.

How Does the Machine’s Footprint and Foundation Differ for Each Gantry Type?

You found the perfect machine, but will it fit in your shop? The machine’s true operating footprint and foundation are hidden costs that can kill a project before it starts.

A moving beam gantry is more space-efficient, with a compact footprint. A fixed beam gantry requires a much larger operating footprint because its moving table needs travel space, often doubling the machine’s effective length.

This is a crucial point that is often misunderstood. With a moving beam gantry4, the machine’s footprint is just the machine itself. The gantry moves back and forth over its fixed table, so it doesn’t need extra room. However, with a fixed beam gantry5, the table moves. To machine a 5-meter-long part, the table needs 5 meters of travel. This means your total required floor space is the length of the machine plus the length of the table’s travel. This can easily double the operating footprint, making the moving beam design a far better choice for shops with limited space. The foundation requirements also differ. The moving beam needs a highly stable foundation focused on supporting the rails for the dynamic gantry. The fixed beam needs a large reinforced foundation to handle the vibrations and shifting weight of the heavy moving table.

Footprint & Foundation Considerations

| Aspect | Fixed Beam Gantry | Moving Beam Gantry |

|---|---|---|

| Operating Footprint | Large. Requires space for the table to travel its full length. | Compact. The gantry movement is contained within the base. |

| Space Efficiency | Poor. Not ideal for space-constrained facilities. | Excellent. Optimizes use of available floor space. |

| Foundation Focus | Absorbing dynamic loads from a large, heavy moving table. | Ensuring precision alignment of the rails for the moving gantry. |

Why is the Moving Beam Gantry the Only Scalable Option For Extra-Long Parts?

Do you need to machine parts that are 10, 20, or even 30 meters long? Trying to do this on a traditional machine is impossible, but one type of gantry is specifically designed for this challenge.

The moving beam gantry is the only scalable option for extra-long parts because the workpiece is stationary. You simply extend the floor rails and foundation to accommodate parts of virtually any length, a feat impossible for fixed beam designs.

This is where the moving beam gantry has an unbeatable advantage. On a fixed beam machine, the part sits on a moving table. To machine a longer part, you need a longer table. The cost, weight, and inertia of a massive moving table quickly become impractical. A 20-meter part would require a 20-meter table, more powerful drives, and a foundation to support over 40 meters of table travel. It just doesn’t work. The moving beam gantry solves this problem elegantly. The workpiece, no matter how heavy or long—like an aircraft wing or ship hull section—is mounted to a stationary floor plate. The gantry then travels over the part. Need to machine a longer part? Just add another section of rails. This modular scalability6 makes it the only viable choice for these massive applications.

Scalability: The Defining Advantage

- Workpiece Mounting: Placed on a static floor plate, eliminating practical limits on part weight and length.

- X-Axis Travel: The travel length is limited only by the length of the rails you install.

- Industry Focus: This makes it the go-to solution for machining wind turbine parts, train car frames, and aerospace components.

Conclusion

Your choice boils down to a single question: Is unwavering precision or ultimate size flexibility more critical? For high-accuracy molds on medium parts, choose the stability of a fixed beam. For massive, varied workpieces, choose the scalability of a moving beam.

-

Understanding fixed beam gantries can enhance your knowledge of structural support in machinery. ↩

-

Exploring moving beam gantries will provide insights into their efficiency and application in modern manufacturing. ↩

-

Explore this link to understand how fixed beam design enhances precision in machining, crucial for high-quality outcomes. ↩

-

Explore the benefits of a moving beam gantry for efficient space utilization and reduced footprint. ↩

-

Learn about the limitations of fixed beam gantries, especially in terms of space and foundation requirements. ↩

-

Discover the importance of modular scalability in manufacturing and how it enhances efficiency and flexibility. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.