How to Choose Between TSC and Standard Coolant in a VMC?

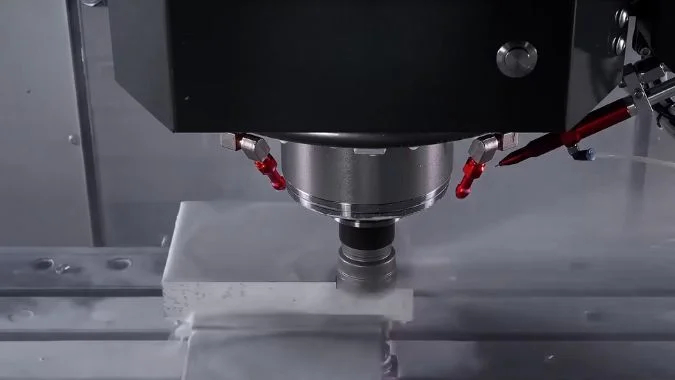

Your tools are wearing out too quickly, and chip buildup is ruining part finishes. Standard flood coolant isn’t reaching the cut, costing you time and money. Through-Spindle Coolant (TSC) is the solution, but is it the right investment for your shop?

Choose standard flood coolant for general-purpose machining and shallow cuts. Select Through-Spindle Coolant (TSC) for deep-hole drilling, aggressive milling of tough alloys, and high-volume production where cycle time is critical. TSC’s high-pressure delivery directly to the cutting edge transforms performance but requires a larger investment.

We’ve seen it countless times: a shop is struggling with machining stainless steel or titanium. The spindle rotation slings most of the external flood coolant away, leaving the cutting edge to overheat. This leads to rapid tool wear and poor part quality. The moment they switch to a machine with TSC, the entire process changes. The high-pressure coolant jet keeps the tool cool and blasts chips out of the way, allowing for faster, more reliable machining. The decision to invest in TSC depends entirely on your application, materials, and production goals.

How Does TSC Fundamentally Change Chip Evacuation?

You’re drilling a deep hole, and the only way to clear the chips is with a slow, repetitive peck cycle. This process is inefficient and dramatically increases cycle times.

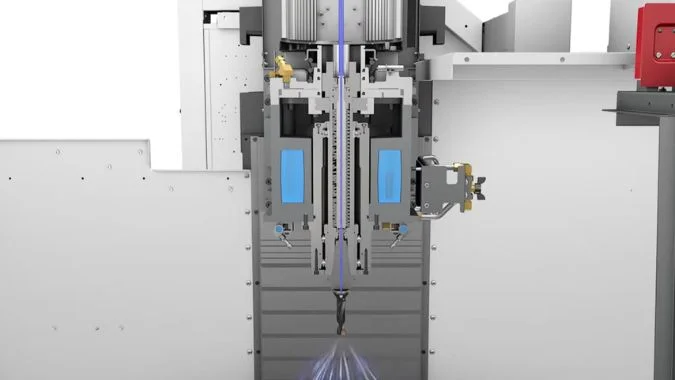

TSC uses a high-pressure jet of coolant (300-1000 psi) fired directly through the tool tip to forcibly blast chips out of the cutting zone. This proactive removal prevents chip packing and recutting, allowing for single-pass drilling and deep pocket milling without interruption.

Standard flood coolant1 is a reactive solution. It tries to wash away chips after they are created, but it often fails to penetrate deep holes or pockets. The chips get packed in the tool’s flutes, which can double the load on the spindle and lead to tool breakage. This forces the use of peck cycles—repetitive in-and-out motions—just to clear debris.

TSC is a proactive solution. It fundamentally changes the physics of chip removal. The focused, high-pressure stream acts like a hydraulic ram, pushing chips up the flutes and out of the workpiece the instant they are formed. This completely eliminates the need for pecking in holes deeper than five times the tool’s diameter. In some cases, this can reduce the cycle time for drilling multiple holes from over 40 seconds down to just 20 seconds—a massive 50% reduction in time. This continuous, reliable evacuation turns a difficult process into a smooth and efficient one.

What are the Specific Tooling Requirements and Cost Considerations for a TSC-Enabled VMC?

You understand the benefits of TSC, but you need to know the true cost. The investment goes beyond just the pump; it affects your tooling, machine, and operational budget.

TSC requires specialized tools and holders with internal coolant passages and a significant upfront investment of $10,000 to $30,000. While operational costs like energy use are higher, the return on investment can be rapid in high-production settings.

Implementing a TSC system requires a complete ecosystem of compatible components. Standard tooling will simply block the coolant flow.

| Component | TSC Requirement | Standard System Requirement |

|---|---|---|

| Cutting Tools | Must have internal coolant channels (through-coolant). | Solid, standard tools. |

| Tool Holders | Sealed collets or hydraulic chucks to prevent high-pressure leaks. | Standard, unsealed holders. |

| Machine | High-pressure pump (20-70 bar), rotary union, and advanced filtration. | Basic low-pressure pump and simple strainer. |

The financial considerations are just as important. The upfront cost for the system is substantial. Specialized through-coolant2 drills and end mills are also more expensive than their solid counterparts. Operationally, the high-pressure pump consumes more energy, about 10-15% more than a standard system. However, TSC is also more efficient with fluid, potentially reducing overall coolant consumption by up to 35%. For a busy shop, the productivity gains from faster cycle times and longer tool life can deliver a return on this investment in just a few months.

How Does Efficient Chip Removal from TSC Directly Improve Part Surface Finish and Accuracy?

You machine a deep pocket and find scratches on the walls and floor. The corners are not as sharp as the print demands. These defects are often caused by chips getting trapped and recut.

By instantly flushing chips away, TSC prevents them from being dragged by the tool, which eliminates recutting. This leads to a superior surface finish, reduces heat distortion, and allows the machine to hold tighter tolerances on complex features.

A pristine surface finish and high accuracy depend on a clean and stable cutting environment. When chips are not evacuated effectively, they get caught between the tool’s cutting edge and the workpiece. As the tool moves, it drags these trapped chips, causing scratches and gouges that ruin the surface finish. This constant grinding also generates excess heat, which can cause the material to warp, leading to dimensional inaccuracies.

TSC solves these issues at the source. The powerful coolant jet ensures a clean cut every time, which has several direct benefits:

- Improved Surface Finish3: It prevents common defects like "bell-mouthing" at the entrance of holes and can improve the overall surface smoothness by up to 10%.

- Enhanced Accuracy4: By minimizing heat buildup, TSC reduces thermal distortion, allowing the part to maintain its intended shape and dimensions.

- Tighter Tolerances: With no chips to deflect the tool, the machine can hold tighter tolerances, which is critical for aerospace and medical components.

What are the Long-Term Maintenance Differences Between a TSC Pump and a Standard Coolant System?

A new machine system should improve your workflow, not add maintenance headaches. You need to know what to expect from a TSC system years down the line.

A TSC system requires diligent, proactive maintenance, especially for its filtration and rotary union, to prevent catastrophic spindle failure. A standard coolant system is far simpler and more forgiving but offers lower performance.

The long-term reliability of a TSC system hinges on keeping the coolant perfectly clean. Any abrasive fines or particles forced into the spindle’s rotary union under high pressure can destroy its delicate seals. This is a critical failure that can allow coolant to contaminate the spindle bearings, leading to a repair that can cost thousands of dollars.

| Maintenance Aspect | Through-Spindle Coolant (TSC) System | Standard Coolant System |

|---|---|---|

| Key Tasks | Daily pressure checks; weekly multi-stage filter cleaning; monthly rotary union and seal inspection. | Periodic tank cleaning; basic strainer/basket cleaning. |

| Primary Risk | Spindle contamination from a failed rotary union seal. This is a catastrophic and expensive failure. | Pump failure or clogged nozzles. These are simple, low-cost repairs. |

| Complexity | High. Requires operator training and a strict, proactive maintenance schedule. | Low. Very simple and forgiving, requires minimal oversight. |

While a standard system is simpler to maintain, a well-maintained TSC system offers its own longevity benefits. By keeping the cutting zone clean and cool, it reduces wear and tear not just on the tools, but on the machine itself.

Conclusion

Choose standard coolant for cost-effective, general-purpose work. For high-performance machining of tough materials, deep features, and high-volume production, TSC is an essential investment that pays for itself in productivity.

-

Learn about the drawbacks of flood coolant and why it may not be effective for deep hole machining. ↩

-

Exploring the advantages of through-coolant tools can enhance your machining performance and tool longevity. ↩

-

Explore this link to understand how improved surface finish enhances product quality and performance in various industries. ↩

-

Discover the significance of enhanced accuracy in manufacturing and its role in achieving precision in production. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.