How to Differentiate Between CNC Milling Machines and CNC Machining Centers?

Are you confused about CNC milling machines versus machining centers? Choosing the wrong one can be a costly mistake, especially when moving from simpler jobs to more complex production. Let me help you understand the key difference easily.

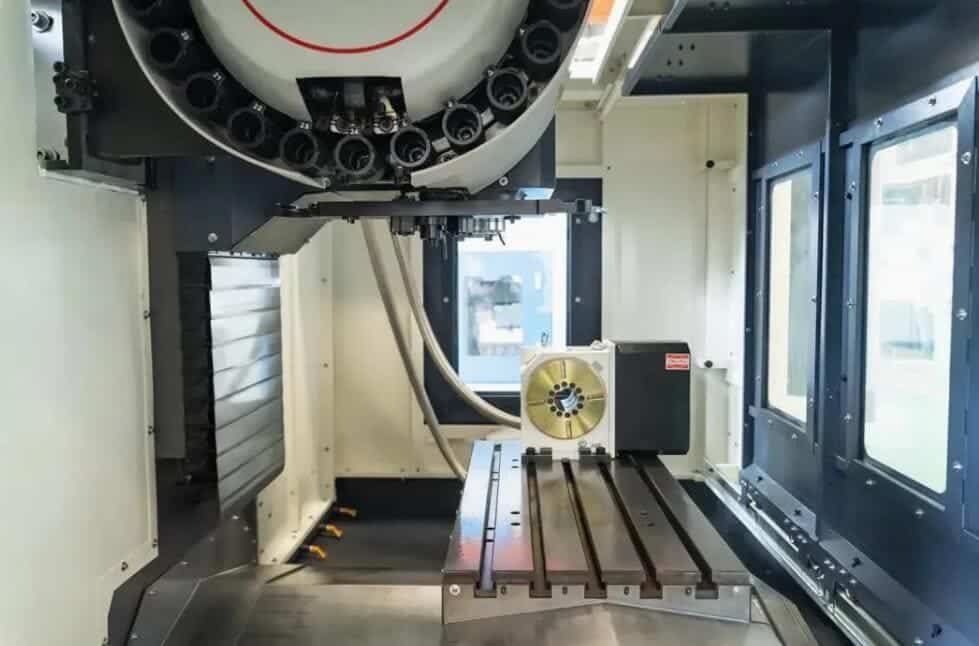

The main difference is the automatic tool changer (ATC) and its tool magazine. A CNC machining center has an ATC, allowing automatic tool swaps during a program. A standard CNC milling machine requires manual tool changes by the operator.

Understanding this core difference is vital. Machining centers, with their automation, are better suited for complex parts needing multiple operations in one setup, boosting productivity. Standard milling machines are often fine for simpler work or when tool changes are infrequent. There’s more to know about machining centers, especially their tool magazines and how they work. Let’s dive deeper into the specifics.

What is the range of tool capacity for a machining center’s tool magazine?

Wondering how many tools a machining center can hold? Picking a machine with the wrong capacity can hurt your efficiency or cost you too much if you don’t need the extra slots. Let’s look at the typical options.

Tool magazine capacity varies widely, typically holding anywhere from 10 to over 200 tools. The exact number depends heavily on the machine’s size, its intended purpose, and the specific type of tool magazine system it uses (like hat, disc, or chain styles).

The number of tools a machining center1 can hold directly impacts how you can use the machine. More tools mean more complex parts can be made in one setup without stopping, or you have backup tools ready when one wears out. This reduces downtime significantly. Based on my experience helping clients select machines at J&M Machine Tools, the tool magazine type2 and capacity are major decision factors.

Common Tool Magazine Types and Capacities

- Hat-type (or Umbrella-type)3: Often found on smaller vertical machining centers (VMCs). They are simple and reliable but generally slower for tool changes (maybe 4-6 seconds). Capacities are usually lower, perhaps 16 or 24 tools. Perfect if you run simpler parts or smaller batches.

- Disc-type (Arm-type/Manipulator)4: These use a mechanical arm for faster changes. They often hold more tools, maybe 24 to 40 or even 60 tools. They cost more and might have limits on tool weight/length. Great for jobs needing more tool variety and faster swaps.

- Chain-type5: You see these on larger horizontal machining centers (HMCs) or big VMCs needing high capacity. They offer the largest storage, sometimes holding 100, 120, or even up to 200 tools. This is essential for highly complex parts (like in aerospace) or long, unattended production runs. The mechanics can be more complex and potentially require more maintenance attention.

Capacity, Machine Size, and Application

The size and type of the machining center often correlate with its tool capacity needs:

| Machine Size/Type | Typical Capacity Range | Common Use Case | Considerations |

|---|---|---|---|

| Small Vertical | 10-24 Tools | Simpler parts, small workshops, training | Lower cost, simpler mechanics |

| Medium Vertical/HMC | 24-60 Tools | General job shops, varied parts | Balances capacity and cost, good flexibility |

| Large Vertical/HMC | 60 – 200+ Tools | Complex parts, aerospace, mold making | High productivity, higher investment & complexity |

For instance, a popular mid-size machine like a Haas VF-26 might offer around a 30-tool changer7 as a common option, fitting that middle ground. Choosing involves balancing the need for many tools (which reduces setup time and allows for more complex parts in one go) against the higher initial cost and potentially increased complexity of larger magazines. Thinking about your current and future part complexity8 is key here.

How does a CNC machining center change tools?

Have you ever watched a machining center swap tools and wondered how it happens so fast? It looks complex, but the machine follows a precise, automated sequence. Let’s break down the common methods.

CNC machining centers use an Automatic Tool Changer (ATC) system. Typically triggered by a code (like M06) in the program, the ATC retrieves the next tool from the magazine, removes the current tool from the spindle, and inserts the new one securely.

The way a machine changes tools affects its speed, complexity, and suitability for different jobs. The whole process is automated, controlled by the CNC. When the program calls for a tool change (often using the M06 G-code), the ATC springs into action. The basic sequence involves the magazine rotating or moving to present the correct tool, the changer mechanism (like an arm) grabbing the new tool and the old tool (sometimes simultaneously), swapping them, and ensuring the new tool is properly clamped in the spindle by the drawbar mechanism. Let’s look at the main ways this happens:

Robotic Arm Tool Changing

This is very common, especially with faster disc-type magazines.

- How it works: A dedicated mechanical arm swiftly grabs the next tool from the ready position in the magazine and, often at the same time, grabs the tool currently in the spindle. It performs a quick rotation or motion to swap them.

- Pros: Very fast tool changes. "Chip-to-chip" times (from the last cut with the old tool to the first cut with the new one) can be under two seconds. Some synchronous systems are even faster, less than a second! This minimizes non-cutting time.

- Cons: More complex mechanics, potentially higher initial cost and maintenance needs.

- Where you see it: High-production environments, machines where cycle time reduction is critical.

Direct Tool Changing

This method involves direct interaction between the spindle head and the tool magazine, often seen with hat-type magazines.

- How it works:

- Magazine-Moving: The tool magazine itself moves towards the spindle, aligns the correct tool pocket under the spindle, and the spindle moves vertically (Z-axis) to pick up or drop off the tool. The magazine then retracts.

- Spindle-Moving: The spindle head moves over to a fixed tool magazine position to perform the exchange.

- Pros: Simpler design, potentially lower cost.

- Cons: Generally slower tool changes compared to arm-type systems.

- Where you see it: Often on lower-cost VMCs or some older machine designs.

Turret Head Tool Changing

This design integrates tools directly into a rotating turret.

- How it works: Instead of a separate magazine and changer arm, the tools (or tool holders) are mounted on a turret. The entire turret rotates to bring the required tool into the cutting position.

- Pros: Extremely fast tool changes (just the turret indexing time), compact structure.

- Cons: Limited tool capacity compared to magazine systems. Best suited for specific machine types or parts.

- Where you see it: Multi-tasking lathes (turn-mill centers), Swiss-type machines, some specialized production machines.

Each method gets the job done automatically, but the speed and mechanical complexity vary significantly.

What factors affect the tool changing time?

Are slow tool changes eating into your production time? Waiting for the machine to swap tools can feel like wasted time and money, directly impacting your output and costs. Let’s look at what causes these delays.

Several factors influence tool change speed: the ATC mechanism’s design speed (arm vs. direct), time needed for spindle orientation, travel distance to the magazine, tool/holder condition (worn, dirty, seized), and machine parameter settings or maintenance state.

Tool change time, often measured as "chip-to-chip" time, is a key performance metric. Reducing this non-cutting time maximizes the time the machine spends actually removing material. Based on my visits to numerous workshops with J&M Machine Tools, several common issues contribute to slow changes:

Core Mechanical Factors

- ATC Type9: As discussed, arm-type changers are inherently faster than direct changers, and turrets are often fastest for their limited capacity. This is built into the machine design.

- Spindle Orientation Time: The spindle needs to stop at a precise rotational angle for the tool change mechanism to engage properly. This orientation process can take 1 to 5 seconds, depending on the machine and motor.

- Travel Distance: The physical distance the spindle head or tool magazine needs to move during the change cycle adds time. This is especially noticeable on large machines or VMCs where significant Z-axis movement might be required to clear the workpiece.

Tool and Holder Condition

- Wear/Damage: Worn pull studs, damaged tool holder tapers, or debris in the spindle taper can prevent smooth clamping or release, causing hesitation, alarms, or requiring manual intervention. Keeping holders and the spindle taper clean is vital. I’ve seen machines struggle simply because of dirty tapers!

- Tool Seizure10: Overtightening, taper damage, or contamination can cause the tool holder to get stuck (seize) in the spindle. This stops the machine completely and requires manual force to remove, risking damage.

Operational Factors

- Tool Management: While less impactful on speed than mechanics, programming the wrong tool or placing it incorrectly can cause errors. Efficient programming avoids unnecessary movements.

- Machine Parameters & Maintenance: Tool change speeds can sometimes be adjusted in the machine’s control parameters (they might be slowed down for safety or during troubleshooting). Poor maintenance, like low pneumatic pressure for actuators or worn guides, can make the ATC sluggish and unreliable.

Here’s a quick summary table:

| Factor | Impact on Tool Changing Time |

|---|---|

| ATC Type (Arm vs. Direct) | Arm types are generally faster |

| Spindle Orientation Time | Adds 1-5 seconds per change |

| Travel Distance | Longer moves (esp. Z-axis) increase time |

| Tool/Holder Condition | Wear/dirt causes delays, seizure stops production |

| Machine Maintenance | Poor upkeep (low air pressure, worn parts) slows operation |

| Control Parameters | Settings can influence speed; may need optimization |

Addressing these through smart programming, diligent maintenance, and operator care minimizes delays.

Does the tool magazine of a CNC machining center need regular maintenance?

Thinking you can just load tools and forget about the magazine? Neglecting maintenance on this critical, active part can lead to frustrating breakdowns, damaged tools or spindles, and costly repairs down the line.

Yes, absolutely. The tool magazine and ATC system require regular maintenance. They are complex mechanical assemblies, and keeping them clean, lubricated, correctly aligned, and adjusted is essential for reliable, fast, and accurate tool changes.

I can’t stress this enough based on field experience: the tool magazine isn’t just passive storage. It involves motors, sensors, chains or gears, arms, pneumatic or hydraulic actuators, and precise alignment with the spindle. Ignoring it is asking for trouble. Proper maintenance ensures everything works smoothly, prevents unexpected failures, and helps the system last longer.

Why Maintenance is Crucial

- Reliability: Prevents jams, tool drops, missed changes, and other failures that halt production unexpectedly. Imagine a tool dropping onto your expensive part!

- Accuracy: Ensures tools are loaded correctly and consistently into the spindle taper. A poorly seated tool leads to vibration, poor surface finish, inaccurate dimensions, and potential damage.

- Longevity: Reduces wear and tear on expensive components like changer arms, cams, bearings, and drive systems. Preventative care is cheaper than replacement.

- Efficiency: Keeps tool change times fast and consistent by ensuring smooth mechanical operation and correct sensor function.

Maintenance Schedule Examples

Always follow the specific machine tool manufacturer’s maintenance manual, as requirements vary. However, a general preventative maintenance schedule often looks like this:

Daily Checks (Operator)

- Visual Inspection: Look for obvious damage, loose parts, heavy chip buildup around the magazine and changer.

- Cleaning: Wipe down accessible areas. Use compressed air carefully to remove chips from pockets and mechanisms (avoid blowing debris into sensitive areas like bearings or sensors).

- Air Pressure/Leaks: Check the machine’s main air pressure gauge; listen for audible leaks near the ATC.

Weekly Checks (Operator/Maintenance)

- Lubrication: Check levels in automatic lubricators. Manually grease points specified by the manufacturer (e.g., arm pivot points).

- Tool Pocket Cleaning: More thorough cleaning of individual tool pockets.

- Chain Tension (if applicable): Check tension on chain-type magazines.

Monthly Checks (Maintenance)

- Sensor Check: Test proximity switches or sensors involved in the tool change sequence for correct operation.

- Filter Cleaning: Clean or replace filters in pneumatic lines feeding the ATC.

- Basic Alignment Check: Visually check alignment between the changer arm, magazine pocket, and spindle.

Annual/Semi-Annual Checks (Qualified Technician)

- Detailed Inspection: Thoroughly inspect for wear on cams, bearings, chains, guides, seals.

- Alignment Verification: Use precision tools (gauges, indicators, maybe even lasers) to verify critical alignments. Adjust as needed.

- Component Replacement: Replace worn seals, O-rings, wipers, or other recommended wear items.

- Full Lubrication Service: Change oil/grease in sealed gearboxes or central lubrication systems associated with the ATC.

Special Conditions: Cutting abrasive materials like cast iron demands more frequent cleaning. Heavy, continuous operation might require more frequent checks of bearings and drive components. Following the manufacturer’s guide is the best policy.

Conclusion

The automatic tool changer is the defining feature separating CNC machining centers from standard CNC milling machines. Understanding magazine capacity, how tools are changed, factors affecting speed, and the necessity of maintenance helps you choose and operate these powerful machines effectively.

-

Exploring the benefits of machining centers can provide insights into their efficiency and versatility in manufacturing processes. ↩

-

Understanding tool magazine types can help you choose the right machining center for your needs, enhancing efficiency and productivity. ↩

-

Explore the benefits of Hat-type tool magazines for efficient machining, especially for simpler parts and smaller batches. ↩

-

Learn how Disc-type tool magazines enhance efficiency with faster tool changes and greater tool variety for complex jobs. ↩

-

Discover the advantages of Chain-type tool magazines for high-capacity needs in complex machining tasks and long production runs. ↩

-

Exploring the specifications of the Haas VF-2 will help you understand its capabilities and how it fits your machining needs. ↩

-

Learning about the benefits of a 30-tool changer can help you optimize your machining process and reduce setup time. ↩

-

Understanding the impact of part complexity on machining can guide your equipment choices and improve efficiency. ↩

-

Discover the various types of ATCs and how they impact machining speed and efficiency. This knowledge can enhance your workshop’s performance. ↩

-

Preventing tool seizure is essential for maintaining productivity. Learn effective strategies to avoid this common issue in machining. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.