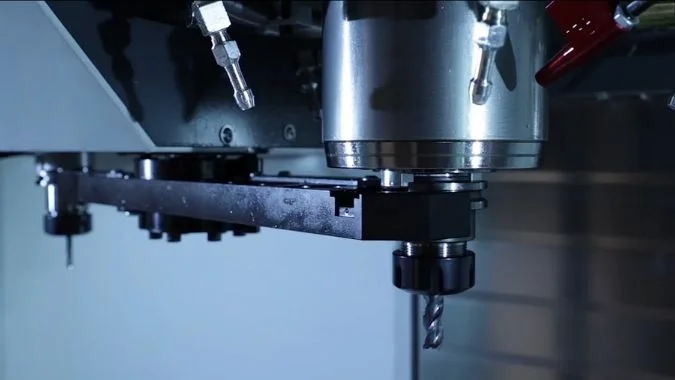

How to Handle ATC Malfunctions in Machining Centers?

A jammed Automatic Tool Changer (ATC) turns your high-speed CNC mill into a useless paperweight. Every minute spent prying a tool loose is money lost. You need to identify, fix, and prevent these failures quickly.

ATC malfunctions usually stem from mechanical wear, pneumatic failures, or sensor errors. To fix them, first inspect the tool change arm and magazine for physical damage or misalignment. Then, verify air pressure levels and check sensor feedback in the diagnostics screen. Regular cleaning and lubrication are critical preventive measures.

Understanding why your ATC fails is the first step to getting your machine back in the cut without calling a service tech.

What Common ATC Malfunctions Occur in Machining Centers?

You command a tool change, but the machine freezes or makes a grinding noise. Recognizing the specific symptoms saves you hours of aimless troubleshooting.

Common ATC faults include inaccurate or failed changes where the tool misses the spindle, physical jamming where the tool gets stuck halfway, and excessive vibration or noise during the arm rotation. You might also see control system alarms triggered by sensor failures or parameter errors.

ATC failures can be categorized into four main buckets.

1. The "Missed Handoff1"

This is the most common issue. The arm swings around, but the tool does not seat into the spindle correctly. It might be off by a few millimeters. The machine stops because the drawbar cannot clamp the pull stud. This is an accuracy failure.

2. The Mechanical Jam2

This is the scary one. The arm tries to pull the tool out, but it is stuck. Or worse, it tries to put a tool in when one is already there. This usually happens because the tool magazine did not rotate to the correct pocket, or the "pot" is not down.

3. The Shakes and Noises

If your tool change sounds like a bag of rocks, something is loose. Excessive vibration usually means the arm or the drive motor is struggling. This affects stability and can eventually lead to a total crash.

4. The Silent Alarm

Sometimes nothing moves at all. The screen just flashes red. This is an abnormal alarm from the control system. The brain of the machine is confused because a sensor says the arm is in two places at once.

| Fault Symptom | Description | Immediate Sign |

|---|---|---|

| Inaccurate Change | Tool misalignment with spindle | Drawbar cannot clamp |

| Jamming | Tool stuck in arm or magazine | Physical blockage, grinding sound |

| Vibration/Noise | Unstable arm movement | Rattling, clunking during swing |

| System Alarm | Machine refuses to move | Error code on screen |

What Causes These ATC Malfunctions?

Blaming "bad luck" won’t fix your machine. These failures have specific physical causes, from worn metal to bad air pressure.

Malfunctions are typically caused by mechanical wear on the arm or locating pins, pneumatic system failures like low air pressure or sticky valves, and control issues such as sensor drift or bad parameters. Lack of lubrication also causes friction that leads to jamming.

Why did the tool change fail? It is usually one of three culprits: air, wear, or sensors.

Mechanical Wear and Tear3

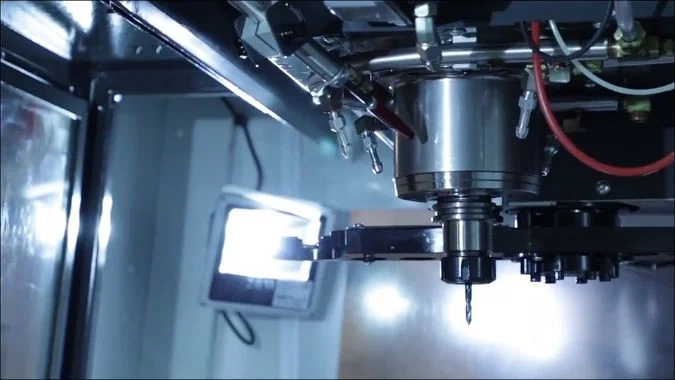

The ATC arm is the hardest working part of the machine. The fingers that grab the tool, the locating pins, and the internal gears wear down over time. If the "keys" on the arm are worn, they cannot hold the tool straight. This causes the misalignment I mentioned earlier. Also, insufficient rigidity in the arm connections leads to that vibration you hear.

Pneumatic Problems4

Most ATCs use air cylinders to flip the tool pots up and down. If your shop air pressure drops below 85 PSI, or if a solenoid valve gets sticky with oil and water, the pot won’t move fast enough. The arm swings and hits the pot. Crash.

Control and Sensors

The machine relies on sensors to know where the arm is. Proximity switches get covered in coolant and chips. They send false signals. If the machine thinks the arm is "home" when it is actually under the spindle, the program crashes. Also, incorrect parameters—like the Z-axis tool change height—will cause the arm to bend the tool flange.

How Do We Fix These ATC Malfunctions?

Staring at the error code will not fix it. You need a systematic approach to unjam the arm and restore precision.

To fix accuracy issues, replace worn pins or arms and adjust the Z-axis reference point. For jams, manually release the brake, rotate the arm to a safe position, and remove obstructions. Fix vibration by tightening loose connections, and resolve alarms by cleaning sensors or correcting parameters.

When you have a fault, follow this logic to get back up and running.

Fixing Accuracy and Alignment

If the tool is not lining up, check the mechanical condition first. Are the fingers worn? Replace them. If the parts look good, check the alignment. We often have to adjust the "Tool Change Position5" in the parameters. This aligns the spindle height perfectly with the arm height. Also, check your air pressure. If it is fluctuating, the cylinder cannot complete the stroke.

Unjamming the Arm

For a physical jam, do not force it with a pry bar. You will break the cam box. Most machines have a manual recovery process. You might need to release the motor brake and manually turn the screw to back the arm off the spindle. Check the lubrication. Often, a jam happens because the mechanism is dry. Grease it up.

Silencing the Noise

If the arm is vibrating, check the drive system. Is the belt loose? Is the reducer gear backlash too high? Tighten the connecting bolts. If the servo motor is hunting, you might need to tune the servo gains6, but usually, it is just a loose mechanical connection.

Clearing Control Alarms

If it is a sensor alarm, find the sensor. It is likely covered in metal chips. Wipe it off. Check the LED light on the sensor body. If it does not light up when you put metal in front of it, replace it. Verify your M-codes in the program are correct.

What Maintenance and Preventive Measures Can Help Avoid ATC Malfunctions?

The best fix is the one you never have to make. A simple daily routine can prevent 90% of tool changer failures.

Prevent malfunctions by regularly inspecting the pneumatic system and cleaning sensors. Maintain a strict lubrication schedule to prevent friction in the arm and magazine. Train operators to keep the tool taper clean and the workshop free of dust to protect delicate components.

I tell my customers that maintenance is cheaper than downtime7. Here is your daily plan.

Daily and Weekly Checks

Every day, wipe down the tool change arm. Remove chips that accumulate near the sensors. Check your air gauge. Is the water trap full? Empty it. Water in the air lines kills solenoid valves. Weekly, check the oil cup for the ATC lubricator. The mechanism needs a steady supply of oil to prevent jamming.

Optimize Operations8

Train your guys. Do not load a tool that is too heavy for the magazine. Do not run the rapid override at 100% if you have a heavy tool; slow it down. Make sure the pull studs are tightened correctly. A loose pull stud can cause a catastrophic drop.

Environment Control

Dust is the enemy. If your shop is dirty, that dust gets into the cam box grease and turns it into sandpaper. Keep the top of the machine clean. If you see "sludge" building up on the tool magazine chain, clean it off and re-grease it.

| Task | Frequency | Benefit |

|---|---|---|

| Check Air Pressure | Daily | Prevents weak cylinder action |

| Clean Sensors | Weekly | Prevents false alarms |

| Lubricate Arm/Chain | Weekly | Prevents mechanical jamming |

| Inspect Pull Studs | Monthly | Prevents dropped tools |

Conclusion

ATC faults stop production, but they are predictable. By maintaining your pneumatics, sensors, and mechanical parts, you can keep your automatic tool changer reliable and your spindle turning.

-

Understanding the Missed Handoff can help you prevent accuracy failures in your operations. ↩

-

Exploring the causes of Mechanical Jams can enhance your troubleshooting skills and improve machine reliability. ↩

-

Understanding mechanical wear and tear is crucial for maintenance and longevity of machinery, ensuring optimal performance. ↩

-

Exploring pneumatic problems can help you troubleshoot and prevent costly downtime in automated systems. ↩

-

Understanding the Tool Change Position is crucial for ensuring precise alignment and optimal machine performance. ↩

-

Tuning servo gains can significantly enhance machine efficiency and reduce vibrations, making it essential for optimal operation. ↩

-

Understanding the cost benefits of maintenance can help you save money and improve efficiency in your operations. ↩

-

Exploring optimization strategies can enhance productivity and reduce costs, making your operations more efficient. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.