Are slow drilling and tapping cycles bottlenecking your production, especially when working with smaller components? Relying on separate operations or using a less specialized machine costs valuable time, increases the risk of errors, and ultimately impacts your profitability. Fortunately, there’s a machine optimized precisely for this high-speed, high-accuracy work.

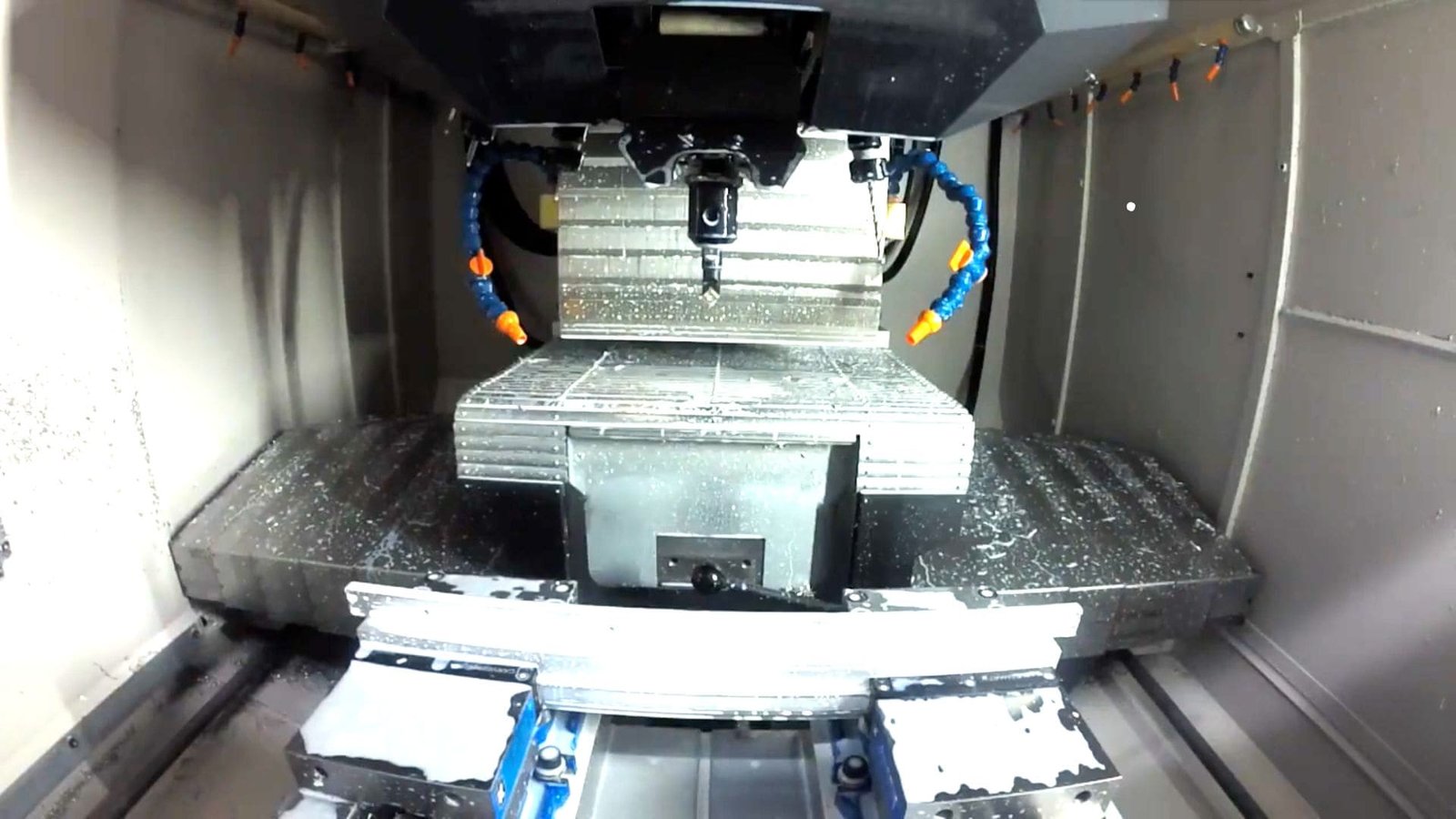

A CNC Tapping Center is a specialized type of CNC machine tool primarily engineered for high-speed drilling and, most importantly, cutting internal threads (tapping). It integrates these functions with rapid tool changes and high spindle speeds to maximize efficiency and precision, particularly on smaller metal parts like aluminum components.

While these machines might resemble compact vertical machining centers (VMCs), their internal engineering is specifically tailored for speed and efficiency in hole-making and threading. You might be asking how they genuinely differ from other machines or why you’d select one. Let’s explore the specific features that make tapping centers the superior choice for certain jobs and industries.

How is a CNC Tapping Center Different from a CNC Drilling Center?

You might think, "My standard drilling center or VMC can tap holes too, so why invest in a dedicated tapping center?" While true, using a general-purpose machine for highly repetitive tapping tasks can significantly slow down your production and potentially compromise thread quality compared to a machine optimized for the job.

The fundamental difference is optimization: Tapping Centers are built for maximum speed and efficiency in both drilling and rapid, rigid tapping cycles. They typically feature faster tool changers (often turret-type) and higher rapid traverse rates than standard Drilling Centers or VMCs, which prioritize broader machining capabilities.

Let’s delve deeper into these distinctions. While a CNC Drilling Machine focuses mainly on creating holes accurately, a Tapping Center is designed from the ground up to drill and thread those holes at the highest possible speed and accuracy.

Key Distinctions Explored

| Feature | CNC Tapping Center | CNC Drilling Center (or VMC) |

|---|---|---|

| Primary Focus | High-speed drilling and optimized tapping cycles | General drilling, milling, tapping; broader versatility |

| Spindle Speed | Typically very high (e.g., 10k-20k+ RPM common) | Variable, often lower top speeds; designed for milling |

| Tapping Method | Optimized for high-speed, precise rigid tapping1 | Capable of rigid tapping, but often slower cycle times |

| Tool Changer | Often turret-type for extremely fast changes (~1 sec) | Arm-type or servo-type, generally slower change times |

| Axis Rapids | Very high rapid traverse rates (e.g., 48+ m/min) | Often slower rapid rates than dedicated TCs |

| Structure | Often compact, rigid cast frame (e.g., Meehant-quality) | Structure varies; built for heavier side loads in milling |

| Typical Use | High-volume, small parts needing many tapped holes | Diverse machining, larger parts, heavier milling ops |

| Cost/Size | Generally smaller footprint and lower initial cost | Typically larger and more expensive |

In practice, while a VMC is a versatile machine, a dedicated Tapping Center will significantly outperform it on jobs requiring numerous drilled and tapped holes. The seconds saved per hole accumulate rapidly in high-volume production. Their design prioritizes minimizing non-cutting time through fast spindle acceleration/deceleration, rapid axis movement, and swift tool changes, ideal for parts like mobile phone housings, electronic components, or small automotive parts.

What are the Real Advantages of a Tapping Center’s High Speed and Rapid Tool Changes?

High spindle speeds (reaching 20,000 RPM or more) and sub-second tool changes look great on paper, but what tangible benefits do they bring to your workshop floor? Slow cycles directly impact profitability and competitiveness. Let’s examine the concrete advantages these high-performance features deliver.

High spindle speeds enable faster cutting (drilling/milling) and quicker tapping cycles, while rapid tool changes drastically cut non-cutting time. This synergy massively shortens overall part cycle times, increases throughput, enhances surface finish and thread accuracy, and ultimately reduces the manufacturing cost per piece.

The impact extends beyond just making parts faster. Here’s a breakdown of the real-world benefits observed when applying these machines correctly.

Tangible Benefits Breakdown

- Massively Improved Machining Efficiency2: This is the primary advantage. High RPMs allow faster feed rates during drilling and light milling. More importantly, the incredibly fast tool changes (often under a second with turret magazines) minimize idle time. For components needing multiple tools (e.g., spot drill, drill, chamfer, tap), this cumulative time saving dramatically reduces the cycle time compared to machines with slower arm-type changers. We often see cycle time reductions of 30-50% or more on suitable parts.

- Enhanced Machining Quality & Consistency: High speeds, paired with appropriate tooling, can reduce cutting forces, leading to better surface finishes and less tool wear. The rigid construction and precise spindle control inherent in tapping centers ensure highly accurate and consistent thread profiles, crucial for assembly. This is particularly important for small or delicate taps prone to breakage. Advanced CNC controls further guarantee positional accuracy and depth control.

- Lower Operating Costs3: Producing more parts per hour directly lowers the cost per part by spreading labor and overheads thinner. Reduced non-cutting time maximizes machine utilization. Efficient drive systems and robust construction designed for repetitive cycles can also lead to lower energy consumption and maintenance costs compared to running a larger VMC for the same tasks.

- Increased Market Competitiveness: Faster production at lower costs enables more aggressive pricing and shorter lead times, providing a significant edge in competitive markets like electronics and automotive components. Consistent high quality further builds reputation.

- Multi-Functionality Within Scope: Although optimized for speed in drilling/tapping, they remain versatile CNC machines capable of handling associated milling, boring, and chamfering operations, allowing many small parts to be completed in a single setup.

These benefits make Tapping Centers exceptionally productive machines when applied to high-volume production of parts rich in drilled and tapped features.

What Industries Typically Benefit Most from Using CNC Tapping Centers?

Are you wondering if this specialized machine aligns with your industry or the components you manufacture? Investing wisely requires understanding where these machines offer the most significant return. Let’s identify the sectors where CNC Tapping Centers deliver maximum value.

Industries demanding high-volume production of smaller parts featuring numerous drilled and tapped holes gain the most. Key sectors include Electronics (3C), Automotive Components, Medical Device Manufacturing, Watchmaking, Small Mold Making, and general Machinery Manufacturing focusing on smaller precision parts.

The unifying factor is the need for speed, precision, and cost-efficiency when producing large quantities of parts with many small threaded holes. Here’s a closer look at their suitability:

Prime Industry Applications

- Electronics Manufacturing (3C – Computers, Communications, Consumer Electronics): Manufacturing parts like mobile phone bodies, laptop chassis, heat sinks, and connectors involves vast quantities of small, precise holes and threads, often in aluminum or light alloys. Tapping centers are ideal for this high-speed, high-volume work.

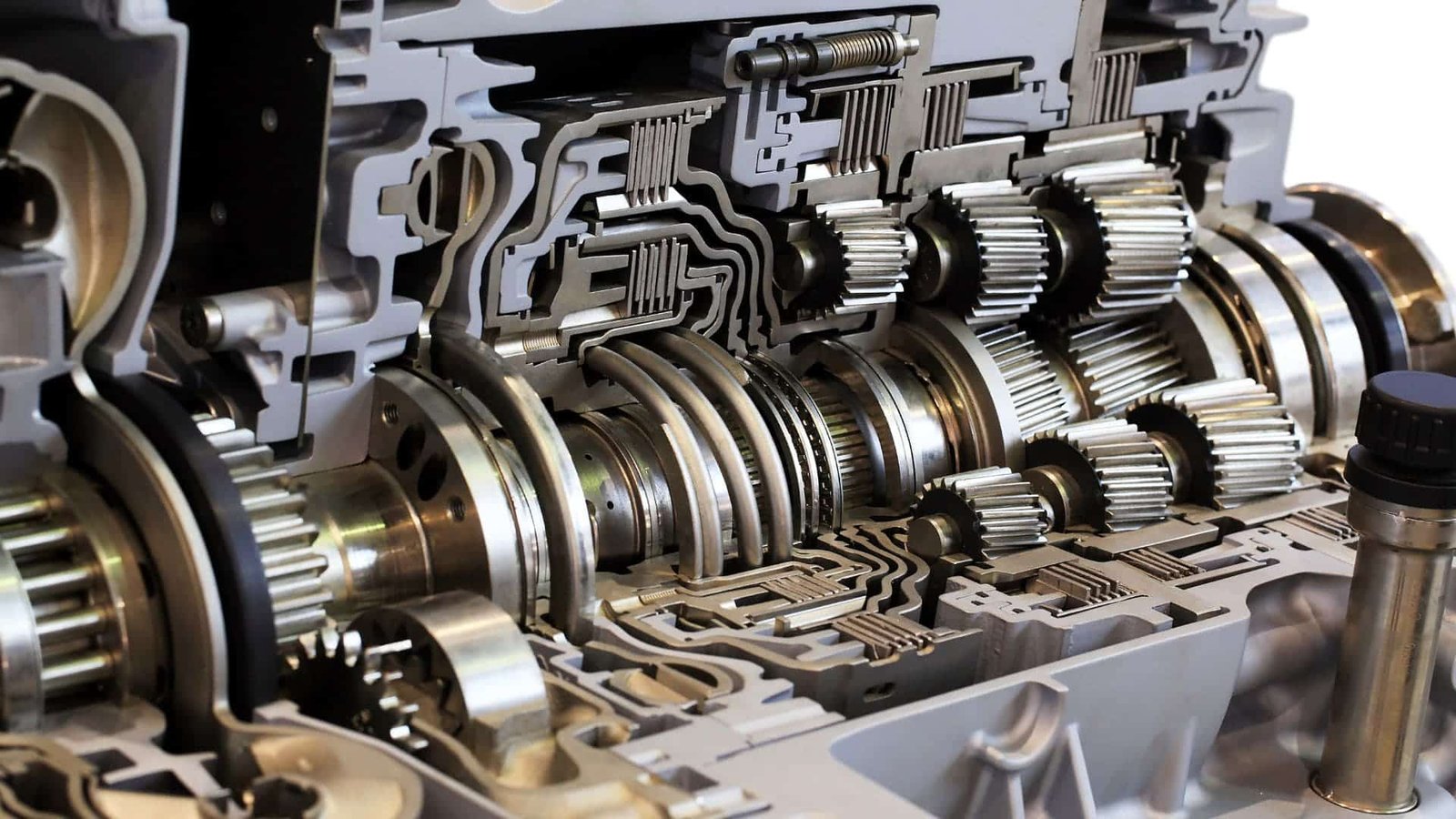

- Automotive Manufacturing: Used extensively for smaller components such as throttle bodies, sensor housings, ECU cases, small engine parts (e.g., covers), and various brackets where numerous tapped holes are required in mass production.

- Medical Device Industry: Producing high-precision parts for surgical tools, diagnostic equipment housings, and implant components often requires intricate drilling and tapping in materials ranging from plastics to stainless steel and titanium. Accuracy and consistency are paramount.

- Watchmaking: The manufacture of tiny, intricate watch components with threaded features benefits greatly from the precision and speed of tapping centers.

- Mold Manufacturing: While larger mold bases require bigger machines, tapping centers excel at producing smaller mold inserts, components, and electrodes requiring accurate hole patterns and threads quickly.

- Machinery Manufacturing Industry: Efficiently produces smaller, high-precision components4 like manifolds, valve bodies, small housings, and brackets used in various types of machinery and equipment.

If your production workflow involves high quantities of smaller parts where drilling and tapping operations consume a significant portion of the cycle time, a CNC Tapping Center5 is almost certainly a highly efficient solution to consider.

What Makes a Manufacturer Choose a Dedicated CNC Tapping Center Over Just Using a Drilling Center?

Since many standard CNC Drilling Centers or VMCs offer tapping cycles, why invest in a dedicated CNC Tapping Center? Isn’t that capability overlap inefficient? The reality is that using a general-purpose machine for highly repetitive, speed-critical tapping can be the less efficient choice. Let’s examine the factors driving the decision towards specialization.

The choice hinges primarily on the sheer volume of tapping required and the critical need for minimum cycle time. If production involves high quantities of parts each demanding numerous taps, the substantial time saved by a tapping center’s optimized speed outweighs the flexibility of using slower tapping cycles on a standard drilling center or VMC.

It boils down to a production efficiency and cost-effectiveness calculation. Here are the typical decision drivers:

Key Decision Factors

- High Tapping Volume & Intensity6: This is the number one reason. If parts require dozens of tapped holes, or if annual production runs into millions of units needing even a few taps each, the cumulative time spent just on tapping becomes a major production factor. A machine purpose-built for speed here offers immense savings.

- Cycle Time Criticality7: In ultra-competitive markets (e.g., consumer electronics, automotive supply), shaving every possible second off the cycle time directly impacts cost and delivery capability. Tapping centers are engineered specifically to minimize non-cutting time in drill-tap intensive cycles.

- Precision & Small Tap Reliability: Dedicated tapping centers offer excellent rigidity and finely controlled spindle acceleration/deceleration, which is crucial for reliably tapping small diameter holes (e.g., M1-M3) without breaking taps, and for maintaining high thread quality standards consistently.

- Operational Focus & Part Mix: If the majority of the work involves drilling and tapping with only light milling, a tapping center completes these dominant operations much faster than a VMC optimized for heavier cutting.

- Automation & Floor Space: Their typically compact footprint makes tapping centers ideal for integration into high-density automated production cells using robots, maximizing throughput per square foot.

- Cost-Benefit Analysis & ROI8: Manufacturers perform a return on investment calculation. Even with a potentially lower initial cost than some VMCs, the justification comes from the significant reduction in cost-per-part due to drastically shorter cycle times, leading to a rapid payback period in high-volume scenarios.

The decision isn’t about whether a VMC can tap; it’s about achieving the required throughput and cost targets when tapping constitutes a large part of the workload.

Conclusion

CNC Tapping Centers are specialized machines optimized for maximum speed and precision in drilling and tapping small components. Their rapid cycle times significantly boost production efficiency, improve quality consistency, and reduce manufacturing costs, making them indispensable in high-volume, competitive industries.

-

Learn how rigid tapping enhances precision and speed in machining processes, making it essential for high-volume production. ↩

-

Explore this link to understand how high RPMs can significantly enhance machining efficiency and reduce cycle times. ↩

-

Learn about effective strategies to lower operating costs in machining, maximizing efficiency and profitability. ↩

-

Learn about high-precision components and their critical role in industries like medical and automotive manufacturing. ↩

-

Explore this link to understand how CNC Tapping Centers can enhance your production workflow and reduce cycle times. ↩

-

Explore how high tapping volume can lead to significant production savings and efficiency improvements in manufacturing processes. ↩

-

Understanding cycle time criticality can help you optimize production processes and improve competitiveness in your market. ↩

-

Learn why cost-benefit analysis is crucial for making informed investment decisions in manufacturing equipment and processes. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.