What is Face Milling? How Does It Work?

Struggling to get smooth, flat surfaces on large parts efficiently? Traditional methods can be slow and inconsistent. This often leads to frustration and wasted material, impacting your bottom line and project timelines.

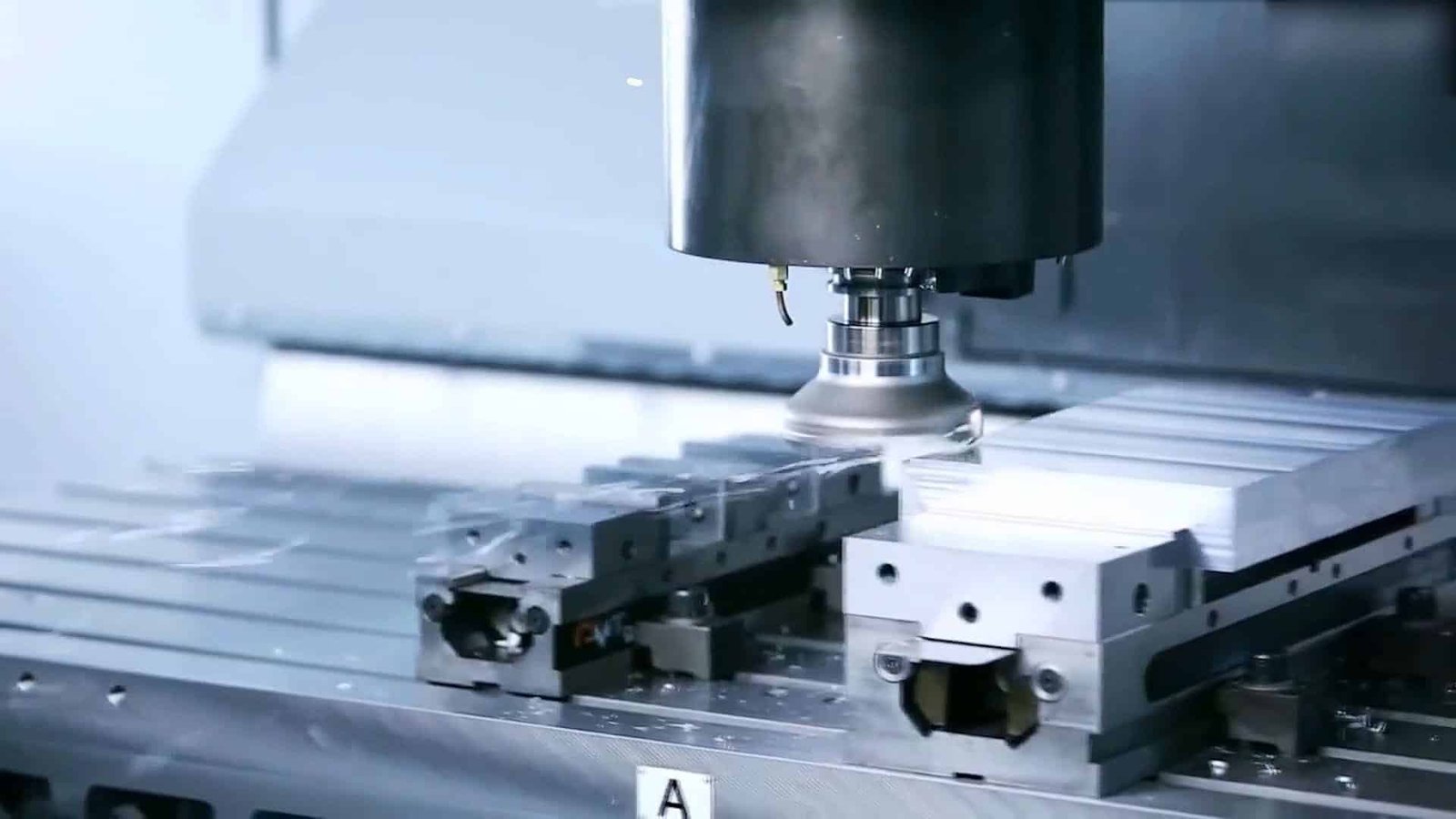

Face milling is a machining process that uses a multi-toothed cutter to create flat surfaces on a workpiece. The cutter’s axis is perpendicular to the surface being machined, allowing for efficient material removal over large areas as it rotates and feeds across the material.

The face milling cutter, usually with a large diameter and multiple cutting edges, spins at high speed while the workpiece moves, allowing the cutting edges to shear away material and form that desired flat plane. It’s not just about spinning a cutter; it’s about the precise interplay of rotation, feed, and robust machine design. We’re going to explore what face milling is all about, from the basic principles to its common applications and how it stacks up against other milling techniques.

What are the Common Face Milling Operations?

Wondering if all face milling is the same? Not quite. Different job requirements call for different approaches, even when just creating a flat surface. You might need speed, the ability to remove a lot of material, or an exceptionally fine finish.

Common face milling operations include general purpose face milling for everyday tasks, high feed milling for rapid material removal at shallower depths, heavy-duty face milling for large stock removal, and finishing operations using specialized inserts for superior surfaces.

I’ve learned that picking the right type of face milling operation for the job, along with the correct tooling, can save a lot of time and extend tool life significantly. It’s about matching the strategy to the specific demands of the material and the desired outcome. Let’s look at the common types:

| Operation | Description | Common Tools/Angles | Key Focus |

|---|---|---|---|

| General Face Milling | Standard procedure for creating flat surfaces on various parts. | 45° lead angle tools; also round inserts, square shoulder | Versatility for roughing & finishing |

| High Feed Milling1 | Uses high feed rates due to chip thinning effect, for rapid material removal at shallower depths (e.g., <2mm). | Small lead angle tools (e.g., ~10°) or specific round inserts | Maximum feed per tooth, speed |

| Heavy Duty Face Milling2 | Removes large volumes of material, generating high cutting forces and temperatures. | Robust tools, often 60° entering angle | Large depth of cut, high stock removal rate |

| Finishing Face Milling3 | Aims for excellent surface finish, often using special inserts. | Wiper inserts alongside standard inserts | Surface quality, aesthetics |

For general face milling, I often rely on cutters with a 45° lead angle as they are very versatile. Sometimes, for specific conditions like creating a sharp 90-degree shoulder next to the flat surface, a square shoulder milling cutter is perfect. Round insert milling cutters are also great for general use and offer excellent strength. High feed milling is fantastic when cycle time is critical; the chip thinning effect lets you push the feed per tooth, sometimes up to 4mm/z, though you’re limited in cut depth. For heavy-duty face milling, especially on rough forgings or castings, you need robust tools that can handle deep cuts and high loads. This often means careful chip management to prevent re-cutting and protect the inserts. Finally, for that mirror-like finish, wiper inserts can make a huge difference, smoothing out the surface beautifully, especially when feed rates are higher.

What are the Advantages and Disadvantages of Face Milling?

Thinking face milling is the perfect solution for all flat surfaces? While it’s incredibly powerful and efficient for its primary purpose, it’s wise to understand its strengths and limitations. This helps in deciding when it’s truly the best choice for your machining tasks.

Face milling excels at producing high-quality flat surfaces efficiently, but it can lead to faster tool wear under heavy loads, requires robust machine tools, and isn’t ideal for very deep material removal or complex 3D shapes.

Face milling is not a magic bullet for every situation. Here’s what I’ve found to be the main pros and cons:

Key Advantages:

- High Efficiency4: This is a major plus. With multiple cutting edges, face mills cover a large area in a single pass, removing material much faster than many other methods for large flat surfaces. This significantly boosts productivity.

- Excellent Surface Quality & Flatness5: When you use sharp inserts and the right cutting parameters, face milling can produce very smooth and highly flat surfaces. The cutting action is generally uniform, which helps achieve this.

- Good Process Control: For creating simple flat surfaces, the process is relatively straightforward to set up and control, allowing for precise material removal and reducing scrap rates.

- Versatility on Machine Types: You can perform face milling on various machines, including those with vertical or horizontal spindles, offering good flexibility.

Potential Disadvantages:

- Faster Tool Wear6: Because of the high cutting forces involved, especially when removing a lot of material or working with tough alloys, the cutting inserts can wear out more quickly. This means regular monitoring and replacement are necessary.

- High Machine Tool Requirements: To handle the cutting forces and maintain accuracy, you need a machine tool that is rigid and stable. A less robust machine can lead to vibrations, poor surface finish, and inaccuracies.

- Not Ideal for Very Large Material Chunks (Compared to Some Methods): While great for surfacing, if you need to remove extremely large volumes of material in deep sections, other processes like peripheral milling might sometimes be more effective for initial roughing.

- Limitations with Interrupted Cuts: It’s generally advised not to face mill directly over existing holes or large slots. The cutter repeatedly entering and exiting the material can stress the cutting edges, leading to premature chipping or tool failure.

- Heat and Chip Management in Heavy Duty Operations: Heavy-duty face milling generates significant heat and a large volume of chips. Effective coolant use and chip evacuation are crucial to protect the tool and workpiece.

Understanding these aspects helps in making informed decisions about when and how to use face milling effectively.

What Industries is Face Milling Applied?

Ever wondered where this fundamental machining process is most critical? Face milling isn’t just a workshop technique; it’s a cornerstone in many major manufacturing sectors. Its ability to create large, flat, and accurate surfaces is invaluable across the board.

Face milling is extensively used in industries like aerospace for aircraft components, automotive for engine and transmission parts, mold manufacturing for precision surfaces, and heavy equipment manufacturing for large structural elements.

From my experience, almost any industry that works with metal at scale relies heavily on face milling. It’s just so effective and efficient for creating foundational flat surfaces or achieving precise thicknesses. Here are some key areas where I’ve seen it make a huge impact:

- Aerospace7: This industry demands extreme precision and often deals with large, complex components. I’ve seen face milling used for creating flat mating surfaces on structural parts, preparing surfaces for assembly, and ensuring the flatness of wing panels or fuselage sections. Specialized techniques, sometimes called mirror milling, are even used for thinning large aircraft skins while maintaining incredible accuracy.

- Automotive Manufacturing: Think about engine blocks, cylinder heads, transmission casings, and brake components. Many of these parts require perfectly flat surfaces for sealing or assembly. Face milling is a high-volume workhorse here, ensuring components meet tight tolerances efficiently.

- Mold and Die Manufacturing: The accuracy of a mold directly impacts the quality of thousands or even millions of parts. Face milling is crucial for machining the flat parting lines where mold halves meet, as well as for creating flat surfaces within mold cavities and cores.

- Heavy Equipment Manufacturing: For large workpieces like those found in construction machinery, agricultural equipment, or power generation, face milling with large-diameter shell mills is common. It allows for efficient surfacing of extensive areas, ensuring components are flat and fit together correctly.

- General Mechanical Manufacturing: This is a broad category, but essentially any time you have a raw casting, forging, or a piece of steel that needs a flat reference surface, or needs to be brought to a specific thickness, face milling is often the first and most efficient operation.

Its ability to quickly produce accurate flat surfaces makes it indispensable across these diverse and demanding fields.

What is the Difference Between Face Milling and Other Milling Processes?

Is face milling just another name for milling, or is it distinct? While all milling involves removing material with a rotating cutter, face milling has specific characteristics in terms of tool geometry, cutter orientation, and primary application that set it apart from other common milling operations like end milling or peripheral milling.

Face milling primarily creates large flat surfaces with the cutter axis perpendicular to the workpiece, using the "face" of the tool. This differs from end milling, which uses the end and periphery of the cutter often for pockets and slots, and peripheral milling, which uses the cutter’s side with an axis parallel to the surface.

While you can sometimes use an end mill to flatten a small surface, a dedicated face mill is designed for efficiency and quality on larger flat areas. The way the tool engages the material is quite different. Let’s look at a more detailed comparison:

Face Milling vs. Peripheral Milling8:

| Feature | Face Milling | Peripheral Milling (Slab Milling) |

|---|---|---|

| Cutter Axis | Perpendicular to the machined surface | Parallel to the machined surface |

| Cutting Area | Uses cutting edges on the face (end) of the tool | Uses cutting edges on the periphery (side) of the tool |

| Typical Use | Creating large flat surfaces, finishing | Machining large flat surfaces, often deeper cuts |

| Material Removal | Efficient for wider, shallower cuts | Can be effective for deeper, narrower cuts |

| Tool Example | Face mill, shell mill | Slab mill, plain milling cutter |

I find peripheral milling is sometimes chosen for very heavy stock removal on machines designed for it, like horizontal milling machines, because the forces are directed differently.

Face Milling vs. End Milling9:

| Feature | Face Milling | End Milling |

|---|---|---|

| Primary Use | Large flat surfaces, initial surfacing | Pockets, slots, contours, edges, smaller flats, 3D shapes |

| Cutter Axis | Perpendicular to the machined surface | Perpendicular (for pockets/floors) or parallel (for profiling edges) to surface |

| Tool Design | Large diameter, multiple inserts on the face | Smaller diameter, cutting edges on end and/or periphery (flutes) |

| Cut Depth | Generally shallower per pass (e.g., up to ~2.8mm for some tools, but can be more in heavy duty) | Can make deeper axial cuts (plunging) and radial cuts |

| Surface Finish (Ra) | Can achieve very fine finishes (e.g., 0.4 µm) | Variable (e.g., 0.29–0.95 µm), depends heavily on tool & strategy |

| Versatility | Specialized for flat surfaces | Highly versatile for various 2D and 3D features |

| Interchangeability | Face milling tools cannot do most end milling tasks | End mills can perform some limited face milling on small areas (less efficiently) |

While an end mill can skim a small surface flat, it’s much less efficient than a face mill for larger areas. A face mill is designed to sweep across the surface, engaging multiple teeth simultaneously for rapid, even material removal. End mills are the champs for intricate details, pockets, and contouring. Choosing the right process is key to efficiency and quality.

Conclusion

Ultimately, face milling is a vital and highly efficient machining process for creating precise flat surfaces. Its various operations cater to different needs, from rapid stock removal to fine finishing, making it indispensable in key industries like aerospace, automotive, and manufacturing.

-

Explore this link to understand how High Feed Milling can enhance efficiency and reduce cycle times in your machining processes. ↩

-

Discover the best tools for Heavy Duty Face Milling to ensure optimal performance and durability in demanding machining tasks. ↩

-

Learn how Finishing Face Milling techniques can significantly enhance the surface finish of your machined parts, ensuring high-quality results. ↩

-

Exploring this resource will provide insights into how high efficiency in face milling can enhance productivity and reduce costs. ↩

-

Discover techniques that can help achieve superior surface quality and flatness, crucial for high-precision machining. ↩

-

This link will offer strategies to mitigate tool wear, ensuring longer tool life and better performance in milling operations. ↩

-

Discover how face milling techniques enhance precision in aerospace manufacturing, ensuring safety and performance. ↩

-

Discover the benefits of peripheral milling, especially for heavy stock removal, and how it compares to other milling techniques. ↩

-

Learn about end milling’s versatility and its specific applications for intricate designs and features in machining. ↩

Chris Lu

Leveraging over a decade of hands-on experience in the machine tool industry, particularly with CNC machines, I'm here to help. Whether you have questions sparked by this post, need guidance on selecting the right equipment (CNC or conventional), are exploring custom machine solutions, or are ready to discuss a purchase, don't hesitate to CONTACT Me. Let's find the perfect machine tool for your needs.